- Details

- Category: Windtech Future

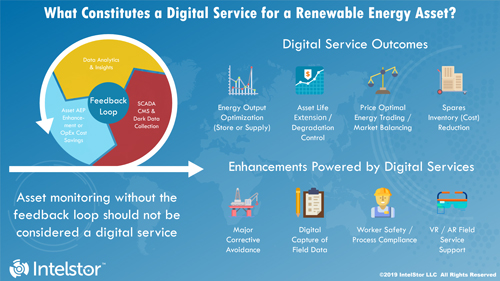

The contribution of digital services to operations and maintenance (opex) cost savings, service revenue enhancement, asset life extension and additional power delivered to the grid in a price optimal fashion has so far fallen short of expectations in the five years since these solutions were first deployed.

The contribution of digital services to operations and maintenance (opex) cost savings, service revenue enhancement, asset life extension and additional power delivered to the grid in a price optimal fashion has so far fallen short of expectations in the five years since these solutions were first deployed.By Philip Totaro, Founder and CEO, IntelStor, USA

- Details

- Category: Windtech Future

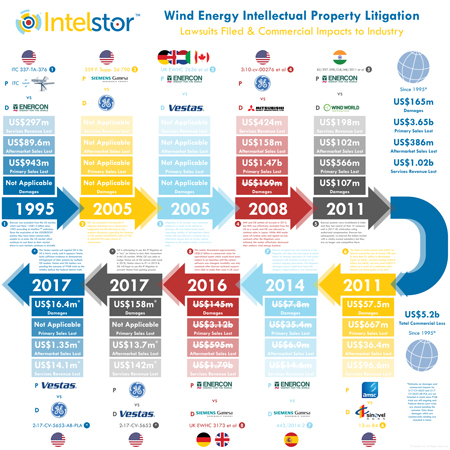

Since 1995 the wind energy industry has suffered more than US$ 5.2 billion in commercial losses associated with intellectual property risks which went unmitigated and could have been avoided.

Since 1995 the wind energy industry has suffered more than US$ 5.2 billion in commercial losses associated with intellectual property risks which went unmitigated and could have been avoided.By Philip Totaro, Founder and CEO, IntelStor, USA

- Details

- Category: Windtech Future

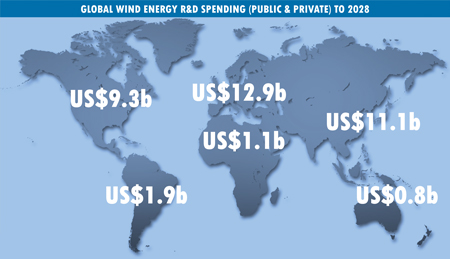

As the wind turbine market enters a new era driven by subsidy-free and tax-credit-free cost parity, a new generation of wind energy technology is poised to hit the market by 2020. Markets which are shifting towards a competitive tendering process continue to drive the need for higher annual energy production as well as lower capex, opex and levelised cost of electricity.

As the wind turbine market enters a new era driven by subsidy-free and tax-credit-free cost parity, a new generation of wind energy technology is poised to hit the market by 2020. Markets which are shifting towards a competitive tendering process continue to drive the need for higher annual energy production as well as lower capex, opex and levelised cost of electricity.By Philip Totaro, Founder and CEO, IntelStor, USA

- Details

- Category: Windtech Future

With more than US$ 647 million of foreign direct investment in offshore wind project development and domestic supply chain ramp-up at stake, Taiwan risks losing its mantle as one of the hottest offshore wind energy markets in the world. At the heart of this is the change in the feed-in tariff, which could face a steep reduction.

With more than US$ 647 million of foreign direct investment in offshore wind project development and domestic supply chain ramp-up at stake, Taiwan risks losing its mantle as one of the hottest offshore wind energy markets in the world. At the heart of this is the change in the feed-in tariff, which could face a steep reduction.By Philip Totaro, Founder and CEO, IntelStor, USA

- Details

- Category: Windtech Future

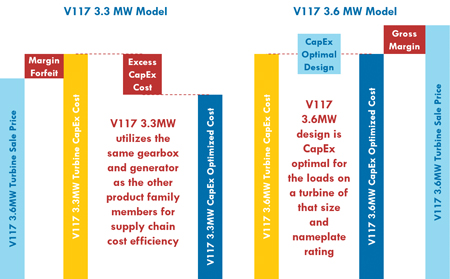

The era of auctions and tenders is well and truly upon the wind energy industry, and the supply chain is already starting to feel the pinch. Some companies have reported tighter and in some cases negative margins in their Q3 and Q4 quarterly financial disclosures as they reconcile their business with a largely subsidy-free era.

The era of auctions and tenders is well and truly upon the wind energy industry, and the supply chain is already starting to feel the pinch. Some companies have reported tighter and in some cases negative margins in their Q3 and Q4 quarterly financial disclosures as they reconcile their business with a largely subsidy-free era.By Philip Totaro, Founder and CEO, IntelStor

- Details

- Category: Windtech Future

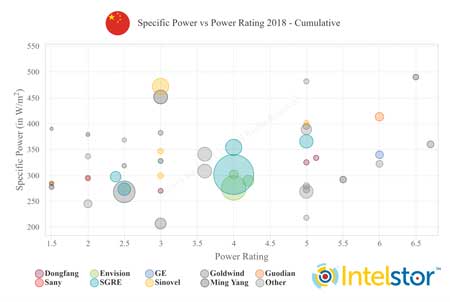

The largely anticipated release of the GE Haliade-X has set the offshore wind industry alight with the anticipated product responses from SGRE and MHI Vestas. However, with most Chinese OEMs still between 3 and 6.7MW in nameplate rating for their offshore wind turbines, what will they do next to compete on product evolution in the Chinese and other Asian offshore markets?

The largely anticipated release of the GE Haliade-X has set the offshore wind industry alight with the anticipated product responses from SGRE and MHI Vestas. However, with most Chinese OEMs still between 3 and 6.7MW in nameplate rating for their offshore wind turbines, what will they do next to compete on product evolution in the Chinese and other Asian offshore markets?- Wind LCOE Set to Drop Further Thanks to the Expiration of Seminal Patents

- The Right Product Mix and a Modular Architecture Can Protect OEM Profits in the Age of Tenders

- Renewable Energy Digitalisation Growth Poised to Reap Benefits for the Data Rich

- Turbine OEMs with Product Portfolio Diversity are Most Successful in US Wind Market

- Enercon Acquisition of Lagerwey Enables Competitive Product Evolution with PMG Technology

- Commercial Value of Data Has Increased Thanks to Digitalisation

- Onshore Wind Turbine Tech to Top Out in Ten Years

- Hybrid Materials and 3D Printing Enabling SciFi Wind Turbine Structures

- Can Wireless Mesh Networks Kill Slip-Rings?

- Offshore Wind Yet to See Meaningful Digital Services Deployment

- Focus on TLPs, Predictive Maintenance and AEP Optimisation to Further Reduce Offshore LCOE

- Renewable energy Internet of Things to hit US$ 5.3 billion annually by 2030

- Onerous Mandates on Performance Impact or Reliability are Stifling RE Innovation

- Emergence of Digital Services Highlights Need for Content Licensing Business Model

- Digitalisation Necessitates New Thinking and New Business Models

- How Common Platform Wind Turbine Architecture Unlocks Export Markets

- Closing the Product Competitiveness Gap

- Offshore Innovation Seeing Lift-off

- Consolidation Spurs Wind Innovation Revival

- The future of technology – Services

- Power plant control

- The Rise of Asian Innovation

- The future of technology – Manufacturing

- The future of technology – Materials

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.