- Category: Windtech Future

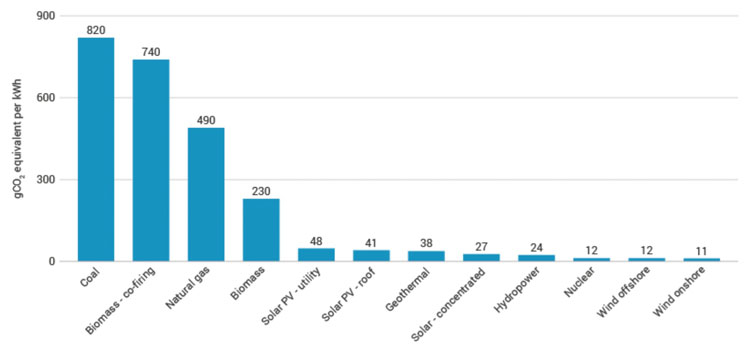

Last year I wrote an article on the good, the bad and the ugly about wind turbines. The ugly was the lack of recycling for turbine blades that in many cases end up in landfills. To check out if anything has been improved since then and, on a larger scale to see how well the wind industry is doing in terms of the carbon footprint, this study follows. As a supporter and enthusiast about wind energy, it is quite important to know how wind turbines are playing their role toward sustainability and net zero emissions targets. In other words, how big is the footprint of a wind turbine?

By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

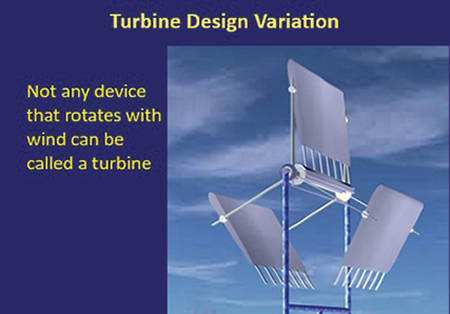

It would be fascinating if we could benefit from wind energy to provide a part of the energy consumption of a building. Many people can have the same sort of thinking, since it is free energy and there is plenty of it. I thought the same way in the beginning, about twenty years ago, when I started learning and working on the subject. Especially now that a lot of work is going on about how smart and sustainable buildings can take advantage of integrating renewable energy into the building, this idea looks more reasonable.

By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

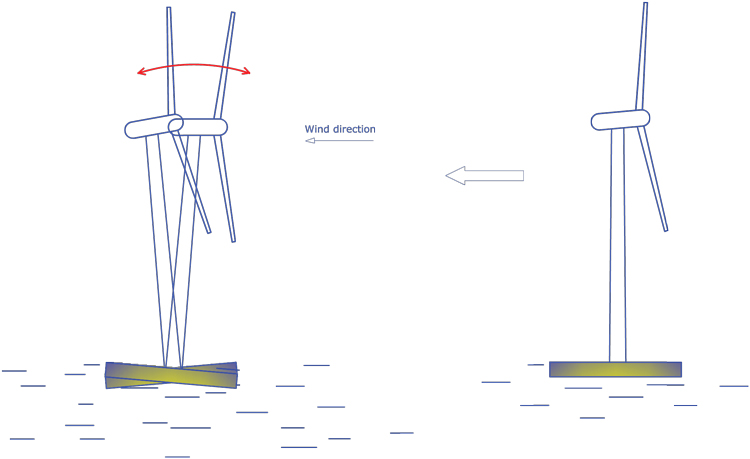

In any complex system with a multipart structure, such as a wind turbine, reducing the number of major components can lead to a reduction in the cost as well as the probability of breakdowns and the associated expenses. Among the major components in a horizontal-axis wind turbine is the yaw system, which any modern large-size wind turbine has. Very old and very small turbines could benefit from a passive system in the form of a wind vane, which was obviously much cheaper than an active yaw system. It would be ideal in a floating wind turbine if the yaw system could be removed, in light of the fact that the floating platform can move/turn and act as a substitute for the yaw system. But is it possible?

In any complex system with a multipart structure, such as a wind turbine, reducing the number of major components can lead to a reduction in the cost as well as the probability of breakdowns and the associated expenses. Among the major components in a horizontal-axis wind turbine is the yaw system, which any modern large-size wind turbine has. Very old and very small turbines could benefit from a passive system in the form of a wind vane, which was obviously much cheaper than an active yaw system. It would be ideal in a floating wind turbine if the yaw system could be removed, in light of the fact that the floating platform can move/turn and act as a substitute for the yaw system. But is it possible?

By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

In the endeavour to reach zero emissions, one of the EU targets is to end the manufacturing of new vehicles that run on fossil fuel by 2035. This means that all new vehicles would be powered by other types of energy. On top of these are electric vehicles and fuel-cell vehicles. For a true zero emission, all energy required by these vehicles must be supplied by renewable energy (green hydrogen for fuel cell vehicles).

By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

In engineering it is well known that larger units of a machine or equipment are better than smaller units from both economical and efficiency viewpoints. For instance, a 1000MW steam turbine is more efficient than two 500MW turbines and certainly better than ten 100MW units. By the same token, for travelling across continents, a jumbo jet is a preferred choice for an airliner, compared to two smaller planes of half capacity. This is why we see, in the case of wind turbines, that manufacturers have been continuously working on making their turbines larger, now in the neighbourhood of 20MW.

In engineering it is well known that larger units of a machine or equipment are better than smaller units from both economical and efficiency viewpoints. For instance, a 1000MW steam turbine is more efficient than two 500MW turbines and certainly better than ten 100MW units. By the same token, for travelling across continents, a jumbo jet is a preferred choice for an airliner, compared to two smaller planes of half capacity. This is why we see, in the case of wind turbines, that manufacturers have been continuously working on making their turbines larger, now in the neighbourhood of 20MW.

By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

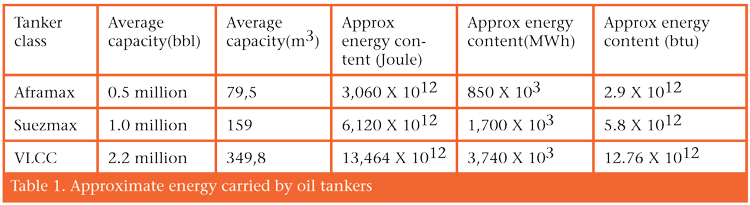

For the past 150 years oil tankers have been used to transport energy (oil) from the production site to the overseas consumption sites. Unless man wants to destroy the living conditions on Earth, this cannot be continued as in the past decades, even if there still exist reserves of fossil oil and gas. The most abundant sources of renewable energy that so far are economically compatible with fossil fuel are solar energy and wind energy. The best scenario for these renewable energies is that they are captured in not so far distances from their consumption sites. These resources, nonetheless, are not evenly distributed on the earth surface, and like oil we need to transport energy from regions of high renewable energy intensity to regions lean in renewable energy.

By Ahmad Hemami, McGill University, Montreal, Canada

- Smart Financial Decisions

- The case of Hywind farm wind turbines

- Lessons for the Future of Wind Energy

- Electric power from very far offshore wind farms

- Is This Similar to The Gearbox Problem?

- Is Using DFIG in Wind Turbines an Obsolete Technology?

- Wind Versus Oil

- Are We Going to Reach Net-Zero Emissions?

- Can Future Wind Turbine Blades Be Modular?

- Not a Catch-22 Problem

- Vertical Axis Wind Turbines, Past, Present and Future

- Gear or No Gear, Not a Battle

- Battery Storage System for Deep-Water Wind Farms

- How Much Is the Cost of Wind Energy?

- Are Turbine Blades With Variable Twist Angle Practical?

- Time to Start Manufacturing Commercial Vertical Axis Wind Turbines

- How Many Wind Turbines Do We Need?

- The Good, the Bad and the Ugly About Wind Turbines

- Two Modes of Operation in Back-to-Back Converters for DFIGs, Is It Worthwhile?

- How Far Will Horizontal Axis Wind Turbines Grow?

- Are We Going in the Right Direction?

- A Design Concept for Future Offshore Wind Turbines

- Wind Turbines in 2100

- Drones or Robots for Blade Repair?

- Should Offshore Floating Wind Turbines be a Larger Copy of Onshore Turbines?

- The Race for Bigger Turbines Continues

- Why We Need More Green Hydrogen for the Global Energy Transition

- Global Gearbox Supply Chain Market Set to Grow to 59.1GW in 2020

- A New Generation of Offshore Wind Turbine Drive-trains Promises Power Ratings up to 16MW

- Renewable Energy Digital Services Benefits Are Not Fully Recognised

- Wind Energy Industry Has Lost US$ 5.2 billion Through Avoidable IP Infringements and Trade Secret Theft

- Wind Energy Industry Research and Development Spending to Top US$ 36.9 billion by 2028

- Feed-in Tariff Turmoil in Taiwan Will Likely Cause the Offshore Wind Industry to Shift Focus to Nearby South Korea

- OEMs are Shifting Towards Global Supply Chain Cost Optimisation at the Expense of Optimal Turbine Levelised Cost of Energy

- With +10MW Offshore Turbines as the New Normal in Europe, Where Do the Chinese OEMs Go Next?

- Wind LCOE Set to Drop Further Thanks to the Expiration of Seminal Patents

- The Right Product Mix and a Modular Architecture Can Protect OEM Profits in the Age of Tenders

- Renewable Energy Digitalisation Growth Poised to Reap Benefits for the Data Rich

- Turbine OEMs with Product Portfolio Diversity are Most Successful in US Wind Market

- Enercon Acquisition of Lagerwey Enables Competitive Product Evolution with PMG Technology

- Commercial Value of Data Has Increased Thanks to Digitalisation

- Onshore Wind Turbine Tech to Top Out in Ten Years

- Hybrid Materials and 3D Printing Enabling SciFi Wind Turbine Structures

- Can Wireless Mesh Networks Kill Slip-Rings?

- Offshore Wind Yet to See Meaningful Digital Services Deployment

- Focus on TLPs, Predictive Maintenance and AEP Optimisation to Further Reduce Offshore LCOE

- Renewable energy Internet of Things to hit US$ 5.3 billion annually by 2030

- Onerous Mandates on Performance Impact or Reliability are Stifling RE Innovation

- Emergence of Digital Services Highlights Need for Content Licensing Business Model

- Digitalisation Necessitates New Thinking and New Business Models