- Category: Articles

The Open Group Extending Open-Source Data Platform to New Energy

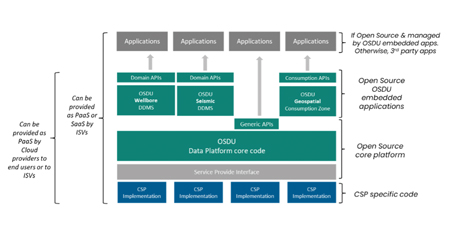

The Open Group Extending Open-Source Data Platform to New EnergyIn 2018, a group of oil and gas companies began exploring how they could share their non-competitive assets, resources and competencies to collaboratively build a common data platform to help them utilise new technologies, such as cloud services, and operate more efficiently. They enlisted the help of The Open Group®, known for its successful stewardship of multiple forums (e.g. Architecture, Security, Process Automation, Open Footprint), to manage the new OSDU™ Forum. In 2021, this group announced the Mercury Release of an open-source data platform with capabilities supporting the subsurface realm of oil and gas. Today and going forward, work continues on expanding the capabilities to oil production, carbon capture, utilisation and storage, and new energy, including wind power. This article gives an overview of the OSDU Forum and an update on the status of its wind project.

By David W. Smith, Solutions Architect, Baker Hughes, USA

- Category: Articles

Harnessing Energy from the Wind at High Altitudes

|

|

By Kristian Petrick, Secretary General, Airborne Wind Europe, Belgium

- Category: Articles

Climbing Robot Performs Leading-Edge Blade Repair in the Field

Leading-edge blade damage can compromise the aerodynamic performance of a wind turbine by up to 3%. A significant problem today, blade damage caused by rain erosion, occurring when the blade hits rain droplets at tip speeds reaching 380km/h, will only become more problematic with the ever-increasing blade lengths of modern turbines. Repairs are complex to perform, requiring not only skilled manual work hundreds of metres above the ground but also specialist tools, polymer coatings, substrate materials and application skills. Blade failure, with the consequence of long turbine downtime, can be the result if the blade is not maintained.

Leading-edge blade damage can compromise the aerodynamic performance of a wind turbine by up to 3%. A significant problem today, blade damage caused by rain erosion, occurring when the blade hits rain droplets at tip speeds reaching 380km/h, will only become more problematic with the ever-increasing blade lengths of modern turbines. Repairs are complex to perform, requiring not only skilled manual work hundreds of metres above the ground but also specialist tools, polymer coatings, substrate materials and application skills. Blade failure, with the consequence of long turbine downtime, can be the result if the blade is not maintained.By Martin Huus Bjerge, CEO, Rope Robotics, Denmark

- Category: Articles

Using Doppler Radar to Document Wind-Energy-Relevant Flow Fields

Using Doppler Radar to Document Wind-Energy-Relevant Flow FieldsSpecialised Doppler radar has continued its emergence as a powerful, complementary technology to provide remotely sensed maps of the wind to serve a broad range of wind energy interests. Rapid scan speeds, excellent along-beam resolution and a large maximum range allow for the simultaneous capture of wind flow fields at disparate scales of motion. Hence, the measurement tool contributes information concurrently to a wide range of issues facing the industry while also collecting weather insights to bolster operational decision-making. The combined deployment of two or more radar systems allows for the construction of synthesised wind fields where the full horizontal wind vector can be resolved over a three-dimensional domain horizontally covering an entire wind farm and vertically extending through the depth of the rotor sweep. As the cost of the early-stage technology continues to decrease in the face of growing wind turbine and wind farm deployment size and complexity, Doppler radar sits uniquely positioned to expand its contribution to the industry in the coming years.

Brian Hirth and John Schroeder, SmartWind Technologies, Lubbock, Texas, USA

- Category: Articles

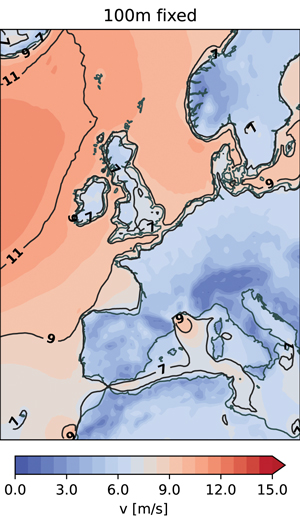

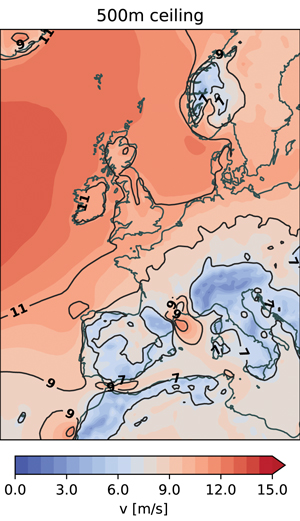

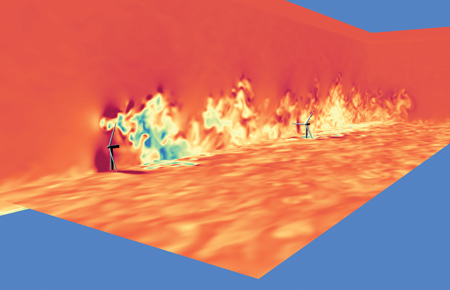

Atmospheric Modelling Using Large-Eddy Simulation

Atmospheric Modelling Using Large-Eddy SimulationThanks to the enormous engineering successes of recent decades, wind energy is now expected to be the central pillar of the energy transition. To continue the success story, however, several grand challenges still need to be met. On the one hand, the challenges are all related to increasing scale: of wind turbines themselves, of clusters of wind farms and of the share of wind energy in the electricity system. On the other hand, the challenges stem from our limited understanding of the atmosphere: of blade aerodynamics, wake effects, interactions between the wind farm and the atmosphere, and running an entire energy system based on the weather.

By Remco Verzijlbergh, Co-founder, Whiffle, the Netherlands

- Category: Articles

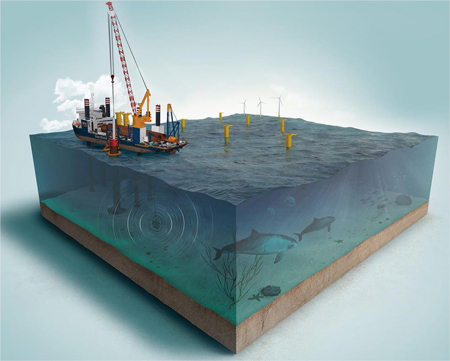

Marine Life Protection

Marine Life ProtectionAcoustic mitigation devices are one of industry-standard solutions for preventing adverse effects of marine infrastructural development works, such as physical interaction with construction equipment or exposure to high levels of underwater sound, they are able to temporarily remove wildlife from a project site and potentially harmful activities. However, not all acoustic mitigation devices are the same, FaunaGuard is a set of species-specific devices which are available for marine contractors and other interested parties to hire. These innovative, welfare-first modular devices create a marine mammal exclusion zone by targeting their respective hearing ranges and repelling them with specialised underwater sound patterns.

By Andrew Gillespie, Marine Protection Products Manager, Ace Aquatec, UK

- Category: Articles

How the Wind Industry Can Accelerate Construction and Deployment

How the Wind Industry Can Accelerate Construction and DeploymentAs demand for carbon-neutral energy production increases around the world, wind generation has gone from strength to strength. Global power output by these means grew by a record 273 TWh in 2021, according to an IEA report (1) – 55 % higher growth than was achieved in 2020. Much of this capacity was driven by new onshore capacity, which is now present in 115 countries around the world. But offshore, the picture is very different. Just 19 countries currently have these kinds of deployments showing the progress we still need to make.

By Peter Richards, Chief Engineer, Fugro, UK

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.