Mooring System Damage Detection in Floating Wind Turbines Through Satellite Positioning

Mooring System Damage Detection in Floating Wind Turbines Through Satellite PositioningA structural health monitoring system has been developed to detect damage in the mooring system of floating wind turbines by analysing the movement of the platform. A cost-effective smart sensor that combines a global navigation satellite system and an inertial navigation unit is used. The collected data is used to create mathematical models when the system is healthy. After the so-called learning period, new incoming data feeds the models, which in turn evaluate the behaviour of the platform compared with the reference situation. If the difference exceeds a threshold, damage in the mooring system is assumed.

By Jon Basurko, Researcher, IKERLAN BRTA, Spain

Results obtained with simulation data show promising results in the detection and even classification ability of some of the different types of damage in the mooring system. Such a tool can help to prevent more serious damage and to schedule inspection and maintenance operations, resulting in a reduction of the levelised cost of electricity.

The mooring system plays a fundamental role in the stability of floating wind turbines. Its inspection is difficult due to harsh environmental conditions and accessibility. If we add to all this the high costs associated with the operation and maintenance of offshore wind farms, it can be concluded that efficient monitoring systems are required.

The mooring system plays a fundamental role in the stability of floating wind turbines. Its inspection is difficult due to harsh environmental conditions and accessibility. If we add to all this the high costs associated with the operation and maintenance of offshore wind farms, it can be concluded that efficient monitoring systems are required.Floating Wind Requires New Monitoring Systems

Important wind resources in the sea beyond the reach of bottom-fixed wind turbines (around 50 metres) has increased the interest in floating wind. Confident of overcoming technological challenges and generating energy at competitive prices, the Global Wind Energy Council foresees the installation of 16.5GW floating wind by 2030.

Important wind resources in the sea beyond the reach of bottom-fixed wind turbines (around 50 metres) has increased the interest in floating wind. Confident of overcoming technological challenges and generating energy at competitive prices, the Global Wind Energy Council foresees the installation of 16.5GW floating wind by 2030.

In a pre-commercial floating offshore wind turbine, the cost associated with the platform and the mooring/anchoring system represents 35% of the capex. The opex of a deep-water offshore wind farm represents 30% of the levelised cost of electricity.

The sensorisation and inspection of the mooring system is a complicated and expensive task. An average maritime wind farm of 500MW with 50 wind turbines will have several hundred mooring lines and anchors. New monitoring systems are required to improve the operation of floating wind turbines.

MooringSense Strategy for Damage Detection

MooringSense Strategy for Damage DetectionMooringSense is a monitoring strategy developed for the mooring system of floating wind turbines. It is a data-driven solution that does not rely on a physical model and follows the classic steps of a statistical pattern recognition paradigm.

On a continuous basis, raw data coming from the smart sensor, environmental buoys and the turbine control is acquired. Data is cleaned and mathematical features are extracted to later be stored. The stored datasets are clustered according to their environmental and operational condition (EOC).

From the stored data, mathematical models for damage detection are generated. These models are tuned for different EOCs. When new data is received, the model is used to detect deviations from the normal operational behaviour. If a predefined threshold is exceeded, an alarm is triggered, indicating a developing fault.

One of the key technologies in this approach is global navigation satellite system technology, which provides the position of a mobile system with sufficient precision and in a cost-effective way.

Description of the Use Case

A 10MW upwind wind turbine is placed on a single-point mooring platform at a site 100 metres deep. The platform is attached to six hybrid mooring lines with the initial and final part made up of chains and the central part of synthetic polyester ropes. The lines are redundant, arranged in pairs every 120 degrees. They have several connectors, a clump weight and buoys. Dragging anchors are selected.

A 10MW upwind wind turbine is placed on a single-point mooring platform at a site 100 metres deep. The platform is attached to six hybrid mooring lines with the initial and final part made up of chains and the central part of synthetic polyester ropes. The lines are redundant, arranged in pairs every 120 degrees. They have several connectors, a clump weight and buoys. Dragging anchors are selected.

A set of damaged mooring conditions was identified, namely line break, anchor drag, buoy loss and lump weight loss. In addition to these, the mooring system suffers degradation over time that affects its mass, thickness, length, stiffness and resistance. Corrosion decreases the diameter of the chain links and their mass and resistant section, slightly lengthening the lines. Marine growth increases the mass of the line and modifies its hydrodynamic resistance. Load cycles cause a change in the stiffness and an elongation of the synthetic rope. All this affects the behaviour of the floating turbine and its movement. Damaged and excessively degraded conditions need to be detected as soon as possible to avoid higher loads in the lines and prevent further damage.

A set of damaged mooring conditions was identified, namely line break, anchor drag, buoy loss and lump weight loss. In addition to these, the mooring system suffers degradation over time that affects its mass, thickness, length, stiffness and resistance. Corrosion decreases the diameter of the chain links and their mass and resistant section, slightly lengthening the lines. Marine growth increases the mass of the line and modifies its hydrodynamic resistance. Load cycles cause a change in the stiffness and an elongation of the synthetic rope. All this affects the behaviour of the floating turbine and its movement. Damaged and excessively degraded conditions need to be detected as soon as possible to avoid higher loads in the lines and prevent further damage.Application with Data Obtained from Simulation

Sensor data was obtained by simulation using commercial software. Hundreds of cases were launched in varying environmental conditions and an error was added to the simulation data to account for sensor error. The environmental parameters include wind speed, orientation, turbulence and wind shear factor, current speed orientation and speed at surface, wave direction, significant wave height and peak period.

Sensor data was obtained by simulation using commercial software. Hundreds of cases were launched in varying environmental conditions and an error was added to the simulation data to account for sensor error. The environmental parameters include wind speed, orientation, turbulence and wind shear factor, current speed orientation and speed at surface, wave direction, significant wave height and peak period.

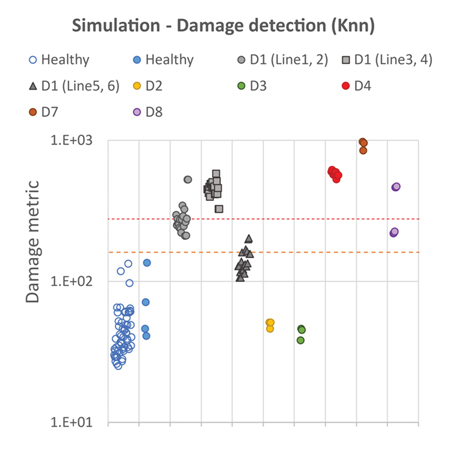

Figure 3 shows how the structural health monitoring system works. The damage detection model was trained with simulation data in which the mooring system was healthy (blue non-filled circles). After that, simulation data with similar EOCs with a damaged mooring system was applied to the model. The model outputs a scalar value – the damage metric – which accounts for the change in the movement behaviour. For a healthy condition, the damage metric (vertical axis) does not exceed a certain threshold. For certain damaged conditions, the damage metric exceeds the threshold.

The analysed damage was coded as follows:

- D1: Line loss

- D2: Clump weight release

- D3: Buoy release

- D4: Line elongation (central synthetic rope part)

- D5: Line stiffness increase

- D6: Locked turret at 0 degrees

- D7: Excessive marine growth

- D8: Anchor drag.

Conclusion

Experimental data obtained from a scaled prototype in an ocean laboratory with different wind and sea conditions was also used to test the proposed strategy. Satisfactory and somehow different and better results were obtained. This is attributed to scaling effects and lower variability in the EOC conditions.

Experimental data obtained from a scaled prototype in an ocean laboratory with different wind and sea conditions was also used to test the proposed strategy. Satisfactory and somehow different and better results were obtained. This is attributed to scaling effects and lower variability in the EOC conditions.

The proposed strategy takes advantage of data-driven models. They do not require complex models based on physics, can be applied to any type of platform and mooring system, and adapt to the peculiarities of each asset. The models can also be built with data from different types of sensors. However, data-driven models need data, usually a large amount, and the models’ diagnostics are limited to what they have previously learned. In contrast, strategies based on physical models can reproduce hypothetical situations, albeit with the inherent limitation of the model and its ability to reproduce reality with sufficient accuracy.

In summary, results show that it is possible to detect certain damage in the mooring system by analysing the movement of the platform. Some damage is more sensitive in certain EOCs than others. As the monitoring system is continuously diagnosing, degradation of the mooring system can be detected in advance and further damage prevented.

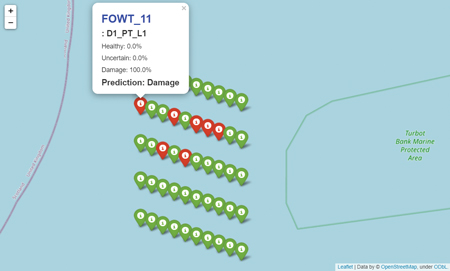

In order to apply the described structural health monitoring strategy, a big data platform able to collect, process and store data from an entire floating wind park and a web interface to monitor the status of the wind turbines has been developed.

MooringSense has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 851703.

Biography of the Author

Jon Basurko is a mechanical engineer and project manager at IKERLAN, part of the Basque Research and Technology Alliance. He is currently focused on condition monitoring of structures and industrial machinery and is interested in applying this methodology to real data.

Jon Basurko is a mechanical engineer and project manager at IKERLAN, part of the Basque Research and Technology Alliance. He is currently focused on condition monitoring of structures and industrial machinery and is interested in applying this methodology to real data.