Techno-Economic Tool for the Optimisation of Offshore Wind Farms Using a Genetic Algorithm

Techno-Economic Tool for the Optimisation of Offshore Wind Farms Using a Genetic AlgorithmThe offshore wind industry has developed rapidly during recent years and is expected to continue expanding over the coming decades. The industry is moving forward, and bigger wind farms are being installed all over the world. Despite the increase in the number of wind farms, the initial investments and operation costs are still relatively high. Reducing the total costs associated with offshore wind farms is crucial to limit economic risks and attract new investors. One of the most notable parts of the total cost is associated with electricity exportation, which is highly influenced by the strategy defined to interconnect the turbines. With the objective of reducing these costs, this article presents a genetic-algorithm-based techno-economic tool that optimises the electric layout considering the loss of revenue due to electric losses inside the wind farm and the purchasing cost of electric cables.

By Mikel Rosell Diez, Engineer, IDOM Consulting, Engineering, Architecture, Spain

The investment and operation costs of modern offshore wind farms (OWFs) are quite significant due to the harsh marine conditions in which they are installed. Additionally, the components and structures of wind turbines are considerably large, which increases the total investments and operation costs. One way of reducing the total cost and making OWFs a self-competitive technology (no need of external economic grants) is to reduce the design costs of the power grid. These costs can either be reduced by maximising the total energy production or by decreasing the cost of produced energy. On the one hand, the energy production mainly depends on the wind conditions, micro-siting and the selected technology of the wind turbines. On the other hand, the cost of produced energy is the sum of the initial investment and operating costs, which depend on the electrical system configuration. The cable connection layout, offshore substation location, selected electrical components and voltage level are critical parameters to be considered when designing an OWF.

Objective

ObjectiveOne way of improving the economic feasibility consists of optimising the electrical layout of the OWF, which depends on the connection between the wind turbines and substations through submarine cables. The transmission and inter-array cables make up 20–30% of total capital expenditure in a commercial offshore wind project and their optimisation is crucial to reduce the levelised cost of electricity of the plant. The cost of the offshore wind power collection system mainly depends on the initial investments in the submarine cables and power losses at the collection system during the whole life cycle of the wind farm. The presented project aims to generate an optimisation tool which is based on inputs defined by the user and finds the optimum configuration to interconnect turbines.

Optimisation Methods

The main objective of optimisation methods is to improve an initial solution with respect to a given objective function until an optimal solution for the problem is obtained. Depending on the defined objective function, the optimisation model will perform a maximising or minimising process. In the offshore wind sector, the objective function can be related to maximising the annual energy production or minimising the foundation or the electrical grid costs, among others. Finding an optimum layout that minimises the cable investment cost and electrical losses can be crucial for the financial profitability of a project.

The main objective of optimisation methods is to improve an initial solution with respect to a given objective function until an optimal solution for the problem is obtained. Depending on the defined objective function, the optimisation model will perform a maximising or minimising process. In the offshore wind sector, the objective function can be related to maximising the annual energy production or minimising the foundation or the electrical grid costs, among others. Finding an optimum layout that minimises the cable investment cost and electrical losses can be crucial for the financial profitability of a project.

Each possible inter-array electrical layout is subjected to a high number of technical and economic variables, which makes it nearly impossible to analyse each possible combination to find the optimum case. Considering that classical optimisation methods cannot be used to solve this kind of problem because of excessive computation time, meta-heuristic models are considered a good solution for cases with a substantially large search space.

Methodology: Genetic Algorithm

Methodology: Genetic AlgorithmMeta-heuristic methods are based on behaviours observed in nature, and the optimisation process simulates various natural processes. For wind farm optimisation methods, literature has demonstrated that genetic algorithms (GAs) provide a balanced solution between computational time and resolution. The study of GAs belongs to the field of evolutionary computation and tries to emulate the Darwinian theory of evolution, which is based on the imitation of biological natural selection and the process of reproduction. Its objective is to find the fittest solution, setting a certain level of randomisation and control. This way, the algorithms can find solutions that other traditional optimisation methods cannot.

A GA analyses a population of candidates rather than single values, which reduces the possibility of finding a local optimum point instead of the global optimum solution. The accuracy of the solution given by the algorithm depends highly on how the candidates’ solutions are encoded as individuals and how the fitness function is defined. Additionally, the level of randomisation and number of iterations strongly influence the performance of the algorithm.

Description of the Optimisation Model

The complete optimisation model combines a GA with the physical and economic model of the wind farm. For that, the user should define certain input parameters:

The complete optimisation model combines a GA with the physical and economic model of the wind farm. For that, the user should define certain input parameters:

- Wind resource time-series that describes the wind resource of the selected area

- Power curve of the selected wind turbine

- Coordinates of the offshore substation

- Cost per kilometre of the inter-array cable

- Resistance per kilometre of the inter-array cable

- Variables to configure the GA.

These parameters are critical to define and calculate the fitness function used by the algorithm to reach a final optimum solution. CrossoverPlot the most efficient configuration in the interface together with total required cable length, energy losses and associated cost

These parameters are critical to define and calculate the fitness function used by the algorithm to reach a final optimum solution. CrossoverPlot the most efficient configuration in the interface together with total required cable length, energy losses and associated costThe flow chart in Figure 1 defines the complete optimisation model, in which all steps conducted before reaching a final solution are illustrated.

Features Considered in the Optimisation ProcessDuring the optimisation process, the algorithm is designed to consider certain features. This way, the user can modify the value of certain parameters and conduct sensitivity analysis and evaluate environmental restrictions that can be encountered in real cases which limits the physical connection between turbines. This way, the user can modify the wind resource data and evaluate the effect on power production. Apart from that, not only are linear array configurations evaluated but also Y-array (non-linear) connections, and the user can define prohibited array tracing zones or obstacles that cables must not cross.

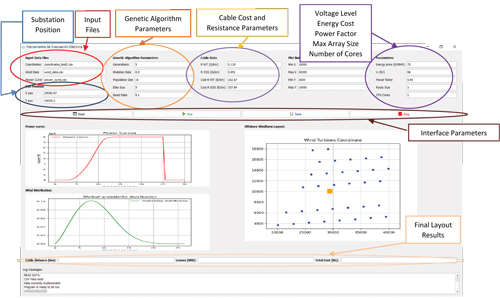

To manage all the parameters to be introduced by the user and have a visual representation of the results obtained, a user-friendly interface has been generated (Figure 2).

Validation and Results

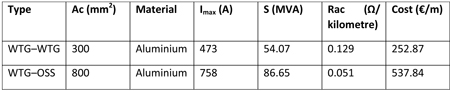

Validation and ResultsThe presented tool is validated and analysed with a hypothetical wind farm to check the feasibility of the program and the quality of the results obtained. The simulated wind farm is composed of 34 wind turbines with a rated power of 14MW each. In total, the wind farm has 476MW installed and is placed in an area with a mean wind speed of 8.33m/s. Following the trend of new wind farms, the inter-array voltage is defined at 66kV with a power factor level of 0.95. Two types of cables are used to connect the collection system: one submarine cable to interconnect wind turbines and one to connect the last turbine of the array to the substation. The characteristics of the cables are defined in Table 1.

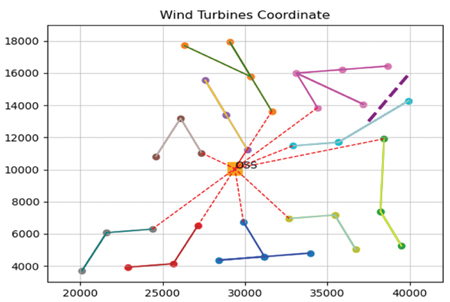

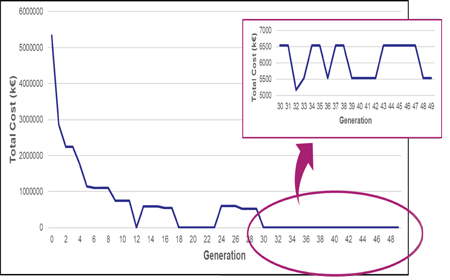

After implementing the defined input parameters, the program is run for 50 iterations. The results shown in Figure 3 illustrate the final layout given by the program, while Figure 4 depicts the reduction of the fitness function in the program in each iteration until final optimisation is reached.

Conclusions

The study concluded that the presented tool is a reliable decision support tool for OWF developers. The user can obtain, in a relatively short period of time, an optimised electrical layout of the collection system that assures that the electrical losses and cable length cost are minimised. As shown in Figure 3, the tool can generate both radial and Y-array configurations and avoids prohibited zones to be crossed by the submarine cable. Additionally, the generated interface allows scalable and flexible implementation of any size of wind turbine, inter-array voltage level and submarine cable deployment.

The study concluded that the presented tool is a reliable decision support tool for OWF developers. The user can obtain, in a relatively short period of time, an optimised electrical layout of the collection system that assures that the electrical losses and cable length cost are minimised. As shown in Figure 3, the tool can generate both radial and Y-array configurations and avoids prohibited zones to be crossed by the submarine cable. Additionally, the generated interface allows scalable and flexible implementation of any size of wind turbine, inter-array voltage level and submarine cable deployment.

Further Reading

- Mitchell, M. 1995. Genetic Algorithms: An Overview. (Adapted from) An Introduction to Genetic Algorithms, Chapter 1. MIT Press, forthcoming.

- Zhao, M., Chen, Z. and Hjerrild, J. 2006. Analysis of the behaviour of genetic algorithm applied in optimization of electrical system design for offshore wind farms. IECON 2006 – 32nd Annual Conference on IEEE Industrial Electronics, 2335–2340.

- Zhang, Y., Qiao, Y., Lu, Z. and Sun, W. 2017. Optimisation of offshore wind farm collection systems-based on modified genetic algorithm. The Journal of Engineering 2017(13), 1045–1049.

Biography of the Author

Mikel Rosell Diez received a BSc degree with honours in automatic and industrial electronical engineering from the University of the Basque Country in 2019 and an MSc degree in renewable energies in the marine environment in 2021. He is currently working as an engineer at IDOM Consulting, Engineering, Architecture in the Offshore & Marine department.

Mikel Rosell Diez received a BSc degree with honours in automatic and industrial electronical engineering from the University of the Basque Country in 2019 and an MSc degree in renewable energies in the marine environment in 2021. He is currently working as an engineer at IDOM Consulting, Engineering, Architecture in the Offshore & Marine department.