Enhancing Circular Economy in the Wind Energy Sector

Enhancing Circular Economy in the Wind Energy SectorWind energy is a major renewable source, but its anticipated threefold increase by 2050 will pose severe environmental and economic challenges for wind energy companies regarding the lack of feasible recyclability of wind blade advanced composite materials. The circular economy approach aims to create value from wind turbine waste by transforming it into new products, but it requires cost-effective and efficient technologies. Although several recycling strategies have been proposed, they have drawbacks in terms of energy, quality or secondary markets. The microwave-assisted technology under development by the CIRCE Technology Centre proposes an electromagnetic-induced selective heating of complex wind blade waste to recover glass/carbon fibres and produce further added-value chemical building blocks from resins that aim to suit petrochemical industry production loops. Microwave degradation shows lower energy input and higher yield than conventional methods. Moreover, it can enable the self-consumption of energy from the wind turbine in its own recycling process, enhancing the sustainability and profitability of the system.

By Alejandro Fresneda and Ignacio Julián, CIRCE, Spain

The challenges and opportunities of wind turbine blade recyclability continue to increase in Europe due to the expansion of installed wind energy capacity, the end of life of existing turbines, and repowering activities. Despite the barely proven techno-economic viability of current recycling strategies, microwave technology may emerge as an energy-efficient solution for wind waste circular economy.

Wind Energy Waste Problem

Wind Energy Waste ProblemDuring the last decade, the proximate end of life of numerous wind farms has triggered the urgency to find sustainable solutions for the recycling of wind turbines and blades. Global policymakers are already reducing wind blade disposal options (i.e. the European Union has already settled on a wide ban on landfilling wind blade waste materials from 2025). While technological development is boosting an increasing repowering of turbines, the anticipated large increase in wind blade waste by 2050 due to decommissioned wind turbines highlights the lack of feasible recycling technologies for the complex material composition of wind blades. Ongoing circular economy strategies aim to recover the fibre and resin components or use them as alternative fuels or raw materials. Thus, recycling wind turbine blades is important for the sustainability and circular economy of the wind energy sector.

Wind Turbine Recyclability

A typical 3MW wind turbine can have up to 25 tons of blade material, which would end up in landfill if not recycled. Wind turbine blades are made of a variety of materials. Metals such as steel, iron, copper and aluminium, along with foams and woods represent a significant 85–90% of the total wind blade structure that may follow traditional recycling pathways. In contrast, wind blades contain 10–15 advanced composite materials formed by glass/carbon reinforced fibres embedded in petro-based complex polymeric organic matrices. Such fibre-reinforced polymers (FRPs) have a unique combination of lightness and resistance to bending, impact and corrosion, among other things. However, they pose great issues when facing end-of-life recycling strategies. At this point, followed pathways for the recycling of these materials include: 1) mechanical shredding and subsequent use in the cement industry (cement kiln method), 2) thermal recycling by pyrolysis/gasification and 3) chemical recycling by solvolysis.

A typical 3MW wind turbine can have up to 25 tons of blade material, which would end up in landfill if not recycled. Wind turbine blades are made of a variety of materials. Metals such as steel, iron, copper and aluminium, along with foams and woods represent a significant 85–90% of the total wind blade structure that may follow traditional recycling pathways. In contrast, wind blades contain 10–15 advanced composite materials formed by glass/carbon reinforced fibres embedded in petro-based complex polymeric organic matrices. Such fibre-reinforced polymers (FRPs) have a unique combination of lightness and resistance to bending, impact and corrosion, among other things. However, they pose great issues when facing end-of-life recycling strategies. At this point, followed pathways for the recycling of these materials include: 1) mechanical shredding and subsequent use in the cement industry (cement kiln method), 2) thermal recycling by pyrolysis/gasification and 3) chemical recycling by solvolysis.

Energy Consumption for FRP Manufacturing for the Wind Blade Industry

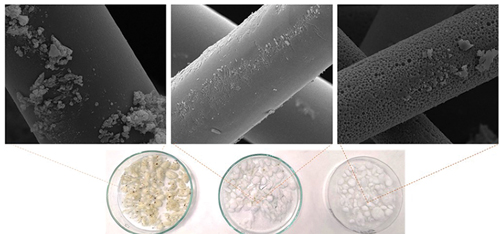

It is desirable not only that the economic feasibility of recycling technology matches the technical requirements of industrialised processes but also that the circular economy approach represents a viable emission reduction option in comparison with the manufacturing of raw materials from virgin feedstocks. Wind blade composite components manufacturing is reported to have very high energy consumption, for example 183–704MJ/kg for carbon fibres, 13–54MJ/kg for glass fibres and 63–80MJ/kg for organic polymeric matrices. It is clear, then, that the biggest challenges faced by recycling technologies for wind blade FRPs are: 1) the recovery of carbon and/or glass fibres from the polymeric matrix of the original compound in an energy-efficient manner and without affecting their mechanical properties (Figure 1); 2) establishing secondary markets for added-value organic by-products without incurring additional energy costs or generating polluting agents.

It is desirable not only that the economic feasibility of recycling technology matches the technical requirements of industrialised processes but also that the circular economy approach represents a viable emission reduction option in comparison with the manufacturing of raw materials from virgin feedstocks. Wind blade composite components manufacturing is reported to have very high energy consumption, for example 183–704MJ/kg for carbon fibres, 13–54MJ/kg for glass fibres and 63–80MJ/kg for organic polymeric matrices. It is clear, then, that the biggest challenges faced by recycling technologies for wind blade FRPs are: 1) the recovery of carbon and/or glass fibres from the polymeric matrix of the original compound in an energy-efficient manner and without affecting their mechanical properties (Figure 1); 2) establishing secondary markets for added-value organic by-products without incurring additional energy costs or generating polluting agents.

Microwave Technology Development

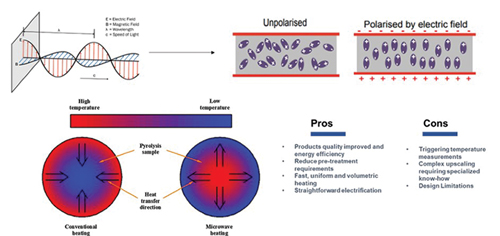

Microwave Technology DevelopmentMicrowave heating technology helps wind blade composite recycling move towards a feasible business model. From this perspective, CIRCE is targeting microwave-assisted heating technology with the potential establishment of viable thermochemical recycling processes. Such technology optimisation is being carried out in the frame of the REFRESH Horizon Europe project, an innovation action to boost a composite value chain maximising the volume and quality of the recovered materials. So far, compared with traditional thermochemical conversion routes, microwave irradiation has been shown to provide drastically decreased processing times (from hours/days to a few minutes), contactless and selective heating of target materials in complex sample mixtures and superior energy efficiency (up to 3 times higher), being a fully electrified and decarbonised process (Figure 2). The selective and fast heating is deemed responsible for the superior performance and quality of the recovered fibres, which allows operation in milder conditions for shorter processing periods. These conditions lead to less damaged fibre surface at a given resin degradation degree.

Microwave Recycling from an Energy Perspective

Prospective energy balance analyses conducted to compare the required energy input for the proposed microwave-assisted recycling technology and the energy generated by a typical wind turbine throughout its lifetime suggest that microwave-assisted blade pyrolysis would consume 2–4% of one year of wind power production, while megawatt solvolysis may be driven by 7–12% of the yearly energy produced by the dismantled turbine. These analyses estimate the power production based on the wind farm’s capacity factor (CF). The CF represents the energy produced relative to the energy at total capacity during the same period. A CF range between 20 and 35% was selected for this evaluation. It is typically considered that the average weight of the blades is 5 tons per MW of nominal power, while the energy required for processes is 15MJ/kg of FRP for microwave-assisted pyrolysis and 50MJ/kg for chemical recycling, including mechanical pretreatment.

Prospective energy balance analyses conducted to compare the required energy input for the proposed microwave-assisted recycling technology and the energy generated by a typical wind turbine throughout its lifetime suggest that microwave-assisted blade pyrolysis would consume 2–4% of one year of wind power production, while megawatt solvolysis may be driven by 7–12% of the yearly energy produced by the dismantled turbine. These analyses estimate the power production based on the wind farm’s capacity factor (CF). The CF represents the energy produced relative to the energy at total capacity during the same period. A CF range between 20 and 35% was selected for this evaluation. It is typically considered that the average weight of the blades is 5 tons per MW of nominal power, while the energy required for processes is 15MJ/kg of FRP for microwave-assisted pyrolysis and 50MJ/kg for chemical recycling, including mechanical pretreatment.

Microwave Heating Homogeneity

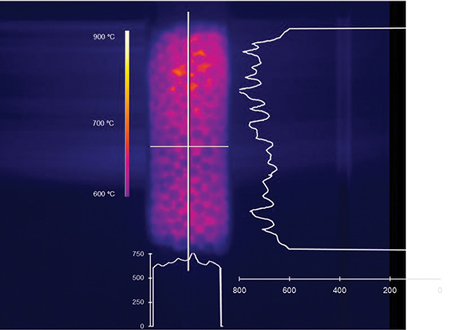

CIRCE is committed to scale-up microwave chemical recycling technologies and includes within its short-term project portfolio the prototyping of a pilot plant based on encouraging bench-scale results. The main challenges that are being faced are: 1) intricate understanding of the physical interaction of microwaves with matter; 2) temperature measurement within a confined electromagnetic field. CIRCE tackles this by performing computational simulations to address the demanding design of reactor cavities (COMSOL Multiphysics) and carrying out experimental validation trials using advanced infrared pyrometers and reactor-wall-transparent thermographic cameras with different spectral ranges as temperature sensors (Figure 3). Controlling thermal heterogeneity in the process is challenging. Typically, the formation of hot spots derived from sample nature and shape impacts chemical efficiency and process performance. CIRCE’s approach adopts reactor ad hoc strategies such as mode and susceptor stirring or fluidisation, which allow us to control the temperature throughout the sample and, thus, the sort of products obtained.

CIRCE is committed to scale-up microwave chemical recycling technologies and includes within its short-term project portfolio the prototyping of a pilot plant based on encouraging bench-scale results. The main challenges that are being faced are: 1) intricate understanding of the physical interaction of microwaves with matter; 2) temperature measurement within a confined electromagnetic field. CIRCE tackles this by performing computational simulations to address the demanding design of reactor cavities (COMSOL Multiphysics) and carrying out experimental validation trials using advanced infrared pyrometers and reactor-wall-transparent thermographic cameras with different spectral ranges as temperature sensors (Figure 3). Controlling thermal heterogeneity in the process is challenging. Typically, the formation of hot spots derived from sample nature and shape impacts chemical efficiency and process performance. CIRCE’s approach adopts reactor ad hoc strategies such as mode and susceptor stirring or fluidisation, which allow us to control the temperature throughout the sample and, thus, the sort of products obtained.

Conclusions

Currently there exists an urgent need for a viable process for wind blade composite recycling technologies from a techno-economic point of view. The large amount of FRPs to recycle in the short and medium term and the fact that current legislation favours investment in recycling processes are key opportunities to boost the technology. However, existing technologies suffer from high energy costs and produced by-products that have a lack of value, whereas no real secondary market exists for further circular pathways. CIRCE Technology Centre is currently committed to electrify and intensify FRP chemical recycling technologies through the use of microwave-assisted technologies. Assuming blade recycling is a necessary step within the whole turbine life cycle, the required energy input for the recovery of fibres and oils by microwave irradiation remains nearly negligible compared with the total power produced by the said turbine during its lifetime. Several ongoing innovation projects, in collaboration with both public and private companies, are advancing the industrialisation of this technology.

Currently there exists an urgent need for a viable process for wind blade composite recycling technologies from a techno-economic point of view. The large amount of FRPs to recycle in the short and medium term and the fact that current legislation favours investment in recycling processes are key opportunities to boost the technology. However, existing technologies suffer from high energy costs and produced by-products that have a lack of value, whereas no real secondary market exists for further circular pathways. CIRCE Technology Centre is currently committed to electrify and intensify FRP chemical recycling technologies through the use of microwave-assisted technologies. Assuming blade recycling is a necessary step within the whole turbine life cycle, the required energy input for the recovery of fibres and oils by microwave irradiation remains nearly negligible compared with the total power produced by the said turbine during its lifetime. Several ongoing innovation projects, in collaboration with both public and private companies, are advancing the industrialisation of this technology.

Biography of the Authors

Alejandro Fresneda has a BSc degree in Chemistry and an MSc in Chemical Sustainability and Energies. After joining CIRCE Technology Centre, he has specialised in thermochemical processes for synthetic oil, biomethane and syngas production. Currently involved in chemical engineering PhD studies in microwave-assisted technologies for waste valorisation, he has joined the Circular Economy Technical Team, focused on technology innovation, decarbonisation strategies and business development.

Alejandro Fresneda has a BSc degree in Chemistry and an MSc in Chemical Sustainability and Energies. After joining CIRCE Technology Centre, he has specialised in thermochemical processes for synthetic oil, biomethane and syngas production. Currently involved in chemical engineering PhD studies in microwave-assisted technologies for waste valorisation, he has joined the Circular Economy Technical Team, focused on technology innovation, decarbonisation strategies and business development.

Ignacio Julián has a PhD in Chemical Engineering and is Microwave Technology Manager at CIRCE Technology Centre. His expertise includes microwave-assisted catalysis, chemical process intensification and thermochemical waste recycling. He has co-authored more than 40 scientific publications. His current interests focus on developing strategies to recycle wind blades in an energy-efficient way through fully electrified processes.

Further Reading

- European Technology & Innovation Platform on Wind Energy (ETIP Wind), Executive committee meeting minutes, 2019. 23/09/2019 . https://etipwind.eu/files/meetings/exco/190923/190923%20EXCO%20meeting%20brussels%20-%20minutes.pdf

- Julian, I., García-Jiménez, A., Aguado, A., Arenal, C. et al. 2022. Advances in the circularity of end-of-life fibre-reinforced polymers by microwave intensification. Chemical Engineering and Processing - Process Intensification 178, 109015.

- Jianli Hu; Benjaram M. Reddy, 03 Nov 2023, Volume, 45, Advances in Microwave-assisted Heterogeneous Catalysis, Chapter 17: Scale-up of Microwave-assisted Heterogeneous Catalytic Processes by Ignacio A. Julian ; Alejandro Fresneda-Cruz

- Branfoot, C., Folkvord, H., Keith, M. and Leeke, G.A. 2023. Recovery of chemical recyclates from fibre-reinforced composites: A review of progress. Polymer Degradation and Stability 215, 110447.