- Details

- Category: Articles

Harnessing Wind Energy Twice per Revolution

Harnessing Wind Energy Twice per Revolution

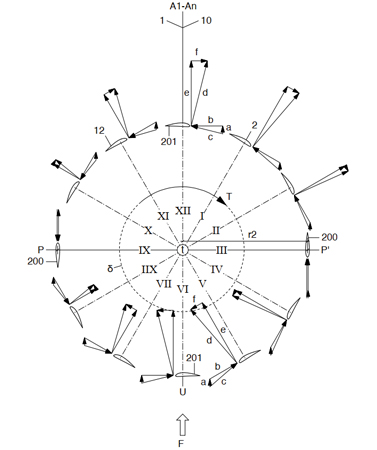

Vertical axis wind turbines (VAWTs) are gaining attention as an alternative to traditional horizontal axis designs because of their ability to capture wind from all directions and reduced visual impact. However, existing VAWT configurations often suffer from performance and structural limitations, hindering their widespread use. This study analyses state-of-the-art VAWT technologies and proposes an innovative framework to address these issues and improve performance. The design integrates advanced aerodynamics, robust structural support, efficient drive mechanisms, and electromagnetic stabilisation to optimise energy conversion and versatility. Key features, such as variable blade positioning and adaptive aerodynamic profiles, enhance energy extraction, grid integration, and resilience. This research demonstrates the potential of integrated VAWT technologies to overcome challenges and enable sustainable energy generation, showcased by four distinct VAWT designs, each with unique characteristics.

By Professor Friedrich Björn Grimm, Founder, RES Institute, Germany

- Details

- Category: Articles

Lidar and Ultrasonic Anemometers Enhance Wind Measurement Accuracy and Propulsion Efficiency

Wind propels innovation not just in power generation but also in other sectors such as maritime transportation. While wind turbines capture the power of air currents to generate electricity, the maritime industry increasingly harnesses wind energy to move ships across the seven seas. With the maritime industry prioritising decarbonisation goals, wind-assisted ship propulsion (WASP) presents a promising approach for reducing vessel emissions. Much like the wind energy industry relies on precise meteorological data for optimal site assessment and turbine efficiency, WASP systems demand accurate and reliable wind measurement for maximum thrust. Recent research indicates a significant evolution in how the industry approaches wind measurement and optimisation, particularly emphasising advanced sensing technologies and data integration strategies. Lidar systems, widely used in wind energy generation to assess potential sites and monitor turbine performance, are now being adapted for use at sea.

Wind propels innovation not just in power generation but also in other sectors such as maritime transportation. While wind turbines capture the power of air currents to generate electricity, the maritime industry increasingly harnesses wind energy to move ships across the seven seas. With the maritime industry prioritising decarbonisation goals, wind-assisted ship propulsion (WASP) presents a promising approach for reducing vessel emissions. Much like the wind energy industry relies on precise meteorological data for optimal site assessment and turbine efficiency, WASP systems demand accurate and reliable wind measurement for maximum thrust. Recent research indicates a significant evolution in how the industry approaches wind measurement and optimisation, particularly emphasising advanced sensing technologies and data integration strategies. Lidar systems, widely used in wind energy generation to assess potential sites and monitor turbine performance, are now being adapted for use at sea.

By Floriane Grussenmeyer, Sales Manager for Maritime, Weather and Environment, Vaisala, France

- Details

- Category: Articles

Century-Old Theory Receives a Physics-Based Update

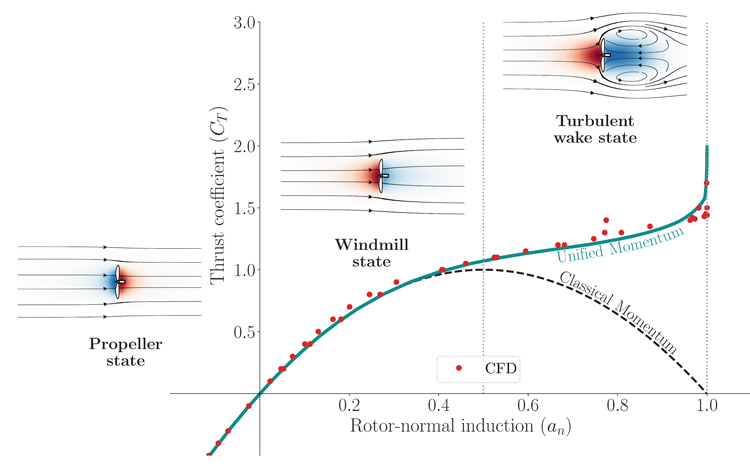

Momentum theory, developed in the late 19th century, is the fluid dynamics foundation for modelling power, forces, and wake properties of a wind turbine. However, turbines often operate in regimes where classical momentum theory breaks down, requiring empirical corrections. Here, from a paper published in the journal Nature Communications, the authors present a physics-based theory derived from first principles which replaces these empirical corrections, creating a new foundation for turbine rotor modelling.

By Kirby Heck, Jaime Liew and Michael Howland, Massachusetts Institute of Technology, USA

- Details

- Category: Articles

A New Frontier in Renewable Energy Innovation

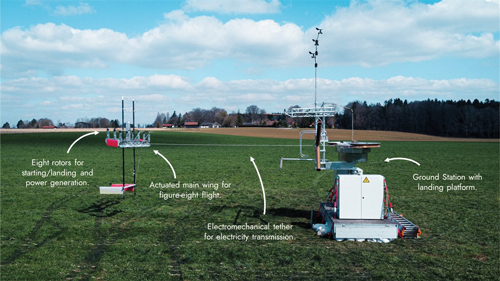

As renewable energy companies race to be at the forefront of the energy transition, the future is converging into a combination of photovoltaics, wind and storage. Innovation in the established wind sector has been slow with a tendency to upscale existing three-bladed turbines. Industry leaders continue to have problems with their technical development and deployment and are expected to not be able to meet future production demands required by the renewable energy development plans formulated by the European Union. Driven by the urge to accelerate the manufacturing and deployability of wind energy solutions, new players enter the field with creative and improved technologies. Kitekraft is leading the way with a radically different approach to harnessing the power of the wind: flying wind turbines.

By Christoph Drexler, Co-founder and Head of Business Development, Kitekraft, Germany

- Details

- Category: Articles

Challenges and Innovations in Wind Farm Performance Assessment

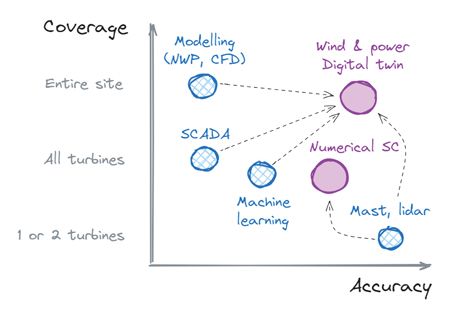

Ensuring that wind turbines operate at their maximum potential is critical for financial sustainability and the broader acceptance of wind energy. Power performance tests are essential to verify contractual turbine characteristics, optimise production, and refine energy yield estimates. Ideally, performance would be continuously monitored with high accuracy for all turbines.

Ensuring that wind turbines operate at their maximum potential is critical for financial sustainability and the broader acceptance of wind energy. Power performance tests are essential to verify contractual turbine characteristics, optimise production, and refine energy yield estimates. Ideally, performance would be continuously monitored with high accuracy for all turbines.

By Samuel Davoust, Co-founder and Science Lead, Tipspeed, France

- Details

- Category: Articles

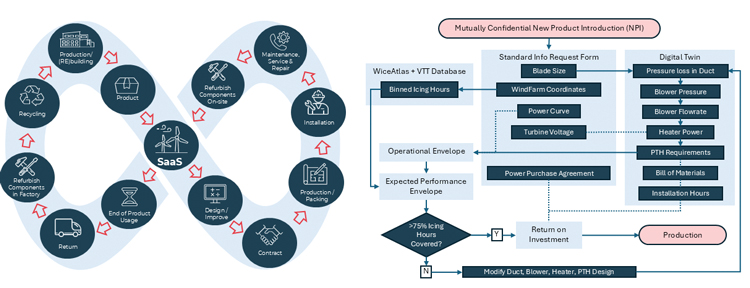

Wind turbine blade icing impacts approximately 65% of wind farms globally, leading to reduced power output, safety risks for workers and the public, and increased wear on turbine components. FabricAir has developed the BorealisWind Ice Protection System (BIPS), an innovative aftermarket solution designed to remove and prevent ice build-up on turbine blades and recover up to 75% of power losses caused by icing. The BIPS is part of FabricAir’s System as a Service model (see Figure 1), which emphasises a cyclical life-cycle approach to optimise performance while reducing the customer’s capex and minimising the product’s environmental impact. This article will use an anonymised case study to step through the life cycle of the BIPS, primarily focusing on the design tools and procedures used during inception.

By Dylan Baxter, PEng, Director of Technology for BorealisWind, FabricAir, Canada

- Details

- Category: Articles

How Weather Intelligence Is the Key to the Energy Transition

How Weather Intelligence Is the Key to the Energy Transition

Globally, countries are in an energy transition, working to replace energy sources that produce carbon dioxide emissions with renewable sources like wind power to reduce emissions by 70% and set the world on the path to meeting climate goals.

By Chris Hyde, Meteorologist, Meteomatics, USA

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.