- Details

- Category: Articles

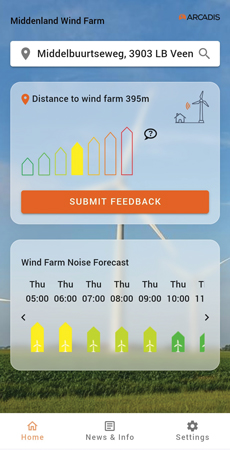

Real-Time Insights into the Impact of Turbine Noise and Shadow Flicker

Real-Time Insights into the Impact of Turbine Noise and Shadow Flicker

As wind energy continues to expand to meet global sustainability goals, its growth often encounters challenges related to community acceptance. To address these concerns, an interactive tool was developed that combines advanced forecasting and community feedback to enhance communication, transparency and mitigation strategies for socially sustainable wind energy development.

By Erik Koppen, Principal Wind Energy and Noise Consultant, Arcadis, the Netherlands

- Details

- Category: Articles

Modular Helical Anchoring Technology

Modular Helical Anchoring Technology

As floating offshore renewable energy technologies, including wind, solar and ocean energy devices, move towards commercial-scale deployment, anchoring and mooring systems are becoming increasingly important. Anchors and moorings represent 10–15% [1] of total capital expenditure in floating wind farms and have a significant influence on foundation design, energy performance, maintenance requirements and decommissioning. Inadequate anchor selection or configuration can lead to increased costs, technical inefficiencies and permitting delays.

By Zachary Miller, Chief Technology Officer and Co-founder, Triton Anchor, USA

- Details

- Category: Articles

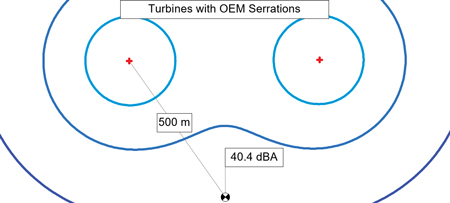

Flexible Serrations Help Lower Low-Frequency Noise While Maintaining Turbine Performance

The issue of wind turbine noise has become a pressing topic in recent years in many areas around the world, especially in Europe. The development of new wind power facilities balances the pursuit of open development areas with optimal wind resources with the practicality of grid connection by situating these facilities closer to areas of higher population. These two drivers are often in tension, and this has led to the development of projects with operation in noise-reduced modes, sacrificing power in the process. This is standard practice in the industry today. Aerodynamic noise has continued to increase as rotor sizes and rated power increases. Although serrated trailing edges have been around for many years in the wind industry to combat this increase in noise, innovation has stalled. At present, serrations deliver around 2dB(A) reductions from a bare blade, yet the situation of noise curtailment remains. Further, these technologies do not typically alter aerodynamic performance, although in practice they have been known to reduce it. As such, there is a desire for technologies that can reduce noise even further without sacrificing aerodynamic performance. The FeatherEdge technology offers a promising advancement in this area, delivering both a noise and power benefit, specifically targeting the low-frequency bands.

The issue of wind turbine noise has become a pressing topic in recent years in many areas around the world, especially in Europe. The development of new wind power facilities balances the pursuit of open development areas with optimal wind resources with the practicality of grid connection by situating these facilities closer to areas of higher population. These two drivers are often in tension, and this has led to the development of projects with operation in noise-reduced modes, sacrificing power in the process. This is standard practice in the industry today. Aerodynamic noise has continued to increase as rotor sizes and rated power increases. Although serrated trailing edges have been around for many years in the wind industry to combat this increase in noise, innovation has stalled. At present, serrations deliver around 2dB(A) reductions from a bare blade, yet the situation of noise curtailment remains. Further, these technologies do not typically alter aerodynamic performance, although in practice they have been known to reduce it. As such, there is a desire for technologies that can reduce noise even further without sacrificing aerodynamic performance. The FeatherEdge technology offers a promising advancement in this area, delivering both a noise and power benefit, specifically targeting the low-frequency bands.

By Ryan Church, CEO, Biome Renewables, Canada

- Details

- Category: Articles

Minimising Environmental Impact and Preventing Energy Loss

Minimising Environmental Impact and Preventing Energy Loss

During wind turbine operation, the gearbox, generator and rotor blades generate noise that is emitted to the environment. The noise from the rotor blades is mainly caused by air turbulence at their trailing edge and blade tip. These operating noises can be perceived as disturbing by residents. Reducing them to a minimum therefore plays an important role in the acceptance of wind energy in the population. This article describes ways of reducing noise at wind turbines using the example of a multimegawatt wind farm in Germany. The focus is on the blade angle adjustment, which ultimately led to compliance with the limit values.

By Martin Peters, Head of Measurement Department, Green Wind Engineering, Germany

- Details

- Category: Articles

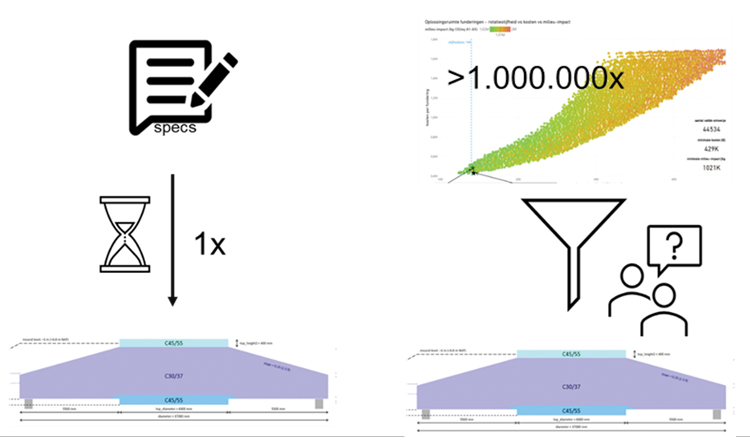

Enhancing Efficiency and Sustainability Through Digital Innovation

With advancements in digitalisation and computational power, data-driven design unlocks new possibilities for optimising wind turbine foundations. Traditional design methods rely on predefined specifications and limited iterations, often leading to conservative and suboptimal solutions. These methods take time for adjustments and can lead to increased material use and costs.

By Chris van der Ploeg, Digital Innovation Lead, Windbase, the Netherlands

- Details

- Category: Articles

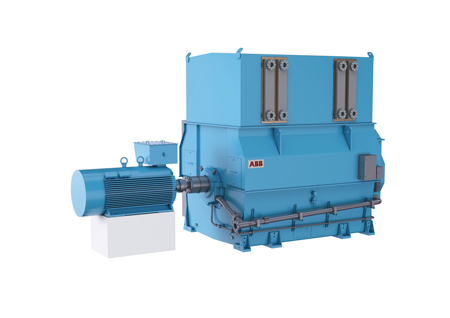

Resurgent Technology Can Maintain Grid Stability in the Renewable Era

Resurgent Technology Can Maintain Grid Stability in the Renewable Era

Renewables are taking over, but they are shaking up grid stability. As fossil fuel plants shut down, we are also losing the vital inertia they provide. The result? A hidden engineering challenge that undermines the reliability of clean power.

By Kristina Carlquist, Head of Synchronous Condenser Product Line, ABB Large Motors and Generators, Sweden

- Details

- Category: Articles

The Role of Continuous Thermal Imaging in Detecting Faults and Reducing Risks

The Role of Continuous Thermal Imaging in Detecting Faults and Reducing Risks

Wind turbines are a critical pillar of renewable energy production, yet they routinely encounter significant operational risks, including overheating, electrical fires, and arc-flash incidents within their nacelle environments. These issues not only threaten the reliability of energy output, they also endanger maintenance personnel, increase operational costs, and contribute to lengthy downtime. Traditional methods of diagnosing these hazards, while long relied upon, are often dangerous, inefficient and prone to data inaccuracies. In response to these persistent challenges, Puget Sound Energy transitioned from conventional diagnostic methods to an advanced, fixed, bispectral infrared camera solution, fundamentally transforming its approach to wind turbine maintenance. This article explores how the adoption of this technology resulted in substantial improvements in technician safety, operational efficiency, real-time diagnostics, and proactive failure prevention, ultimately reshaping best practices for wind energy infrastructure maintenance.

By Troy Goss, Project Manager, Sytis, USA

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.