Sponsored Content

How to Choose the Right Ultrasonic Wind Sensor: Time of Flight (ToF) vs Acoustic Resonance Acu-Res®

Ultrasonic wind sensors, also known as solid-state anemometers, are increasingly being adopted across industrial and environmental applications. With no moving parts and high measurement accuracy, these sensors use sound waves to determine wind speed and direction. Two dominant technologies underpin ultrasonic wind sensing: Time of Flight (ToF) and Acoustic Resonance (Acu-Res®). Understanding the differences between these methods is essential when specifying sensors for mission-critical environments.

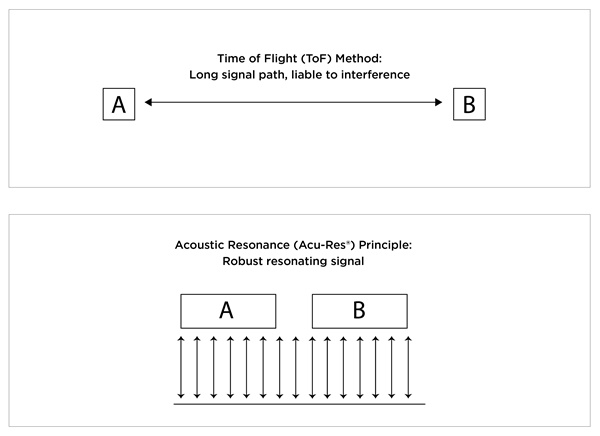

1. Time of Flight (ToF) Technology

Conventional ToF wind sensors measure the time for ultrasonic pulses to travel between transducers. They require a long distance between transducers to ensure precise readings. Simple in principle, but the measurement can be affected by external noise signals, humidity, temperature and air pressure. In practice, ToF sensor accuracy may degrade in fog, ice, salt, dust or the presence of insects. Frequent recalibration and vulnerability to acoustic path distortion are common concerns.

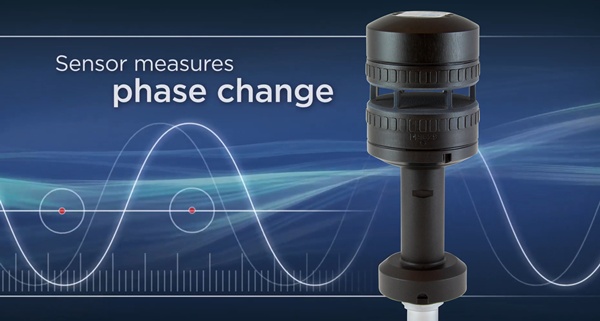

2. Acoustic Resonance (Acu-Res®) Technology

Acoustic Resonance works by generating standing waves in a cavity and monitoring the phase shifts caused by the wind. FT Technologies’ proprietary Acu-Res® technology uses high-frequency ultrasonic waves in a compact resonant chamber. The signal is continuously amplified, enabling an extremely high signal-to-noise ratio. In simple terms, it is immune to external noise, physical shock and vibration. The compact geometry, combined with self-heating features ensures it stays free of ice and moisture; suited for offshore, arctic, desert and tropical conditions, to deliver consistent, reliable performance in extreme environments.

| Feature | Time of Flight (ToF) | Acoustic Resonance (FT Acu-Res®) |

| Measurement Method | Pulse transit time | Phase shift in standing waves |

| Signal Strength | Moderate | Very high (self-amplifying) |

| Sensitivity to Contamination | High | Low |

| Acoustic Path | Exposed (100mm+) | Protected (10mm) |

| Ice Resistance | Large surface area = hard to heat | Up to 3X heating effectiveness |

| Environmental Robustness | Moderate | Very high |

| Size/Form Factor | Medium-large (up to 2kg) | Compact and rugged (< 500g) |

| Calibration Stability | Regular re-calibration | Long-term stability |

| Typical Use Cases | Static, general meteorology | Dynamic, critical control systems |

| Power Consumption | Moderate (high for heating) | Low (energy-efficient heating) |

Why the Right Sensing Method Matters

When evaluating a wind sensor, it may not always be obvious which sensing method is used. Buyers should ask the manufacturer directly whether the device operates using acoustic resonance or not – Acu-Res® is only available from FT Technologies Ltd. This clarity can help ensure the selected sensor aligns the environmental and operational demands of the intended application.

While both ToF and Acoustic Resonance ultrasonic wind sensors have their place, FT’s proprietary Acu-Res® technology offers clear performance advantages in applications where physical resilience, compact design, and accuracy under extreme conditions are non-negotiable. Its ability to maintain precision without compromise leads to longer operating life, lower maintenance, and reliable data during storms, temperature swings, or high-vibration deployments.

Considerations when Choosing Ultrasonic Wind Sensors

When selecting an ultrasonic wind sensor, it’s important to consider factors alongside the measurement principle, especially for offshore applications, industrial, maritime or extreme conditions.

Vibration, Shock, and EMI Resistance: In dynamic applications such as boats, drones, offshore platforms or mobile infrastructure, vibration and shock resistance is mission-critical for accurate wind measurement. Acoustic Resonance (Acu-Res®) ultrasonic wind sensors are specifically engineered to endure and operate throughout continuous mechanical vibrations, resist electromagnetic interference (EMI), and absorb shocks while maintaining data precision.

Material Selection: Ultrasonic wind sensors are manufactured using materials ranging from corrosion-resistant stainless steel to UV-stabilised plastics. For harsh environments like coastal areas or offshore platforms, selecting sensors made from marine-grade metals ensure durability against saltwater and humidity.

Weight and Mounting: The choice of material and measurement method influences the wind sensor’s weight. Lightweight models are ideal for portable weather stations, UAVs, and buoys, whereas more robust models are suited for permanent outdoor installations.

Sealing and Ingress Protection (IP Ratings): Quality sealing mechanisms, from O-rings to precision gaskets, are designed to protect internal components from moisture, dust, and salt ingress. Select sensors with IP66 or IP67 certification, tested and proven for reliable performance in outdoor, maritime, or industrial environments.

Temperature Resistance: Ensure that the wind sensors operate within the expected temperature ranges for your location. Not all ultrasonic wind sensors are designed to handle extreme cold or heat, so it’s vital to verify the manufacturer’s specifications, especially for desert climates, polar regions, or tropical zones.

Real-World Deployment

FT’s Acu-Res® wind sensors have been deployed globally across demanding applications; from offshore wind farms in the North Sea to autonomous surface vessels and industrial drones. In each case, they operate continuously in harsh, high-vibration, and weather-exposed environments where traditional sensors often fail.

With 25 years of field-proven reliability, FT Technologies’ wind sensors are manufactured in the UK to exacting standards and individually calibrated in a wind tunnel before leaving the factory. Renowned for their durability and minimal maintenance requirements, they deliver consistent performance where ToF sensors are prone to drift and require periodic recalibration.

As environmental monitoring and energy systems push into more remote and extreme locations, and demand more from their instruments, wind sensor performance under pressure becomes critical. While ToF sensors remain common in general-purpose use, Acoustic Resonance (specifically FT’s Acu-Res®) implementation is engineered to exceed expectations. For operators requiring reliable data, low maintenance, and compact integration, Acu-Res® technology sets a new benchmark in ultrasonic wind sensing.

Industry Reviews

“After hearing about the reliable performance of the FT sensor and then holding it in my hand and feeling the difference in weight and size, I was convinced. The weather can throw anything at us now. Changing to the FT sensor has made it possible to keep these turbines running, even in our coldest winter conditions.”

Guy Le Blanc, Minnesota Wind Farm

“We are actually amazed that sometimes we see FT sensors that have been on turbines for over 10 years and they are in such good condition that you can’t even tell that they’ve been sitting on the top of a turbine for that long.

And where we have customers with turbines in cold climates, we also feel the FT sensors are best. With their better heating system, they give much better availability for the turbine operator. The FT742-DM50 is a great new model. It is easy to align with the laser tool and, once fitted, you can be sure that it will always be aligned, even if you have to change it”

Anders B. Jensen, CTO of Spica Technology ApS