- Category: Articles

Technologies, Modelling and Costs

Technologies, Modelling and CostsWind turbines are subject to high mechanical and environmental loads, including extreme winds, storms, rain, gravitational load on rotating blades, and temperature and humidity variations. These loads lead to the degradation of wind turbine parts, in particular wind turbine blades. Repair of wind turbine blades can cost many thousands of dollars. Such high costs can influence the wind energy costs in general. Thus, efficient repair of wind turbines is an important element of the renewable energy transition, making wind energy more competitive. In this article, mechanisms of wind turbine blade degradation, repair technologies and possibilities to reduce the repair costs are reviewed.

By Leon Mishnaevsky Jr, Senior Scientist, Technical University of Denmark, Denmark

- Category: Articles

A Remote Condition Monitoring Strategy Can Avoid Uneconomical Operations

|

|

By Mike Hastings, Senior Application Engineer, Brüel & Kjær Vibro, Denmark

- Category: Articles

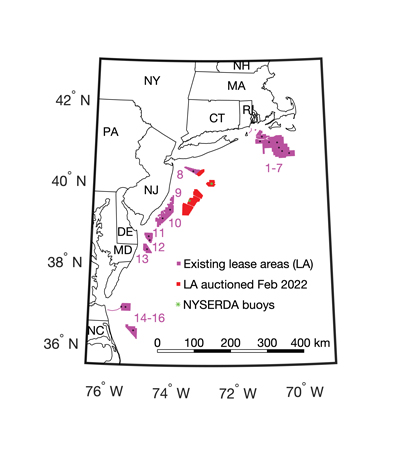

Modelling of Wind, Wave and Wakes for Offshore Wind Energy

Modelling of Wind, Wave and Wakes for Offshore Wind EnergySixteen offshore wind energy lease areas are currently under active development along the US east coast and six more in the New York Bight were recently auctioned for bids of nearly $ 4.4 billion. Observational data is sparse in this region so analyses of numerical simulations pertinent to operating conditions, power and wake production are summarised and used to highlight processes that are worthy of further investigation.

By Rebecca J. Barthelmie, Jeanie A. Aird, Frederick Letson and Sara C. Pryor, Cornell University, USA

- Category: Articles

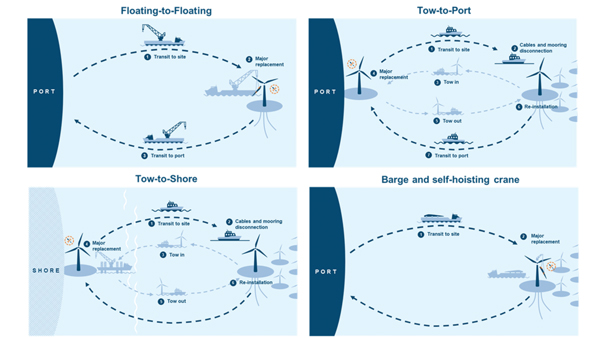

Four Strategies for Major Component Replacement

Four Strategies for Major Component ReplacementThis article details the current state of O&M in floating wind with a particular focus on major component replacement strategies. It summarises year-long discussions held by the expert members of the World Forum Offshore Wind.

By Ilmas Bayati, Peak Wind, Denmark

- Category: Articles

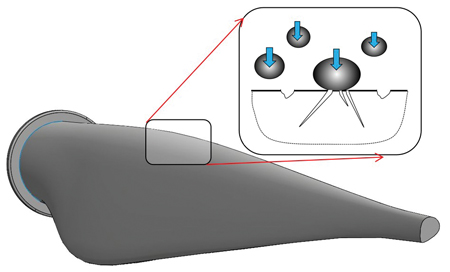

Effects of Erosion on Wind Turbine Leading Edge and Countermeasures

Effects of Erosion on Wind Turbine Leading Edge and CountermeasuresIn recent years, operators of wind farms have become aware of an annoying effect reducing the performance of their turbines – the impact of weather-induced erosion at the rotor blade surface, mainly at the leading edge (Figure 1). Offshore wind parks in particular are impacted, driven by droplets of water hitting the blades with high velocity.

By Jan Liersch and Bastian Sundermann, Key Wind Energy, Germany

- Category: Articles

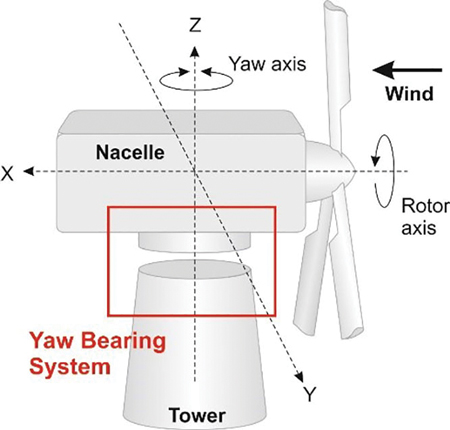

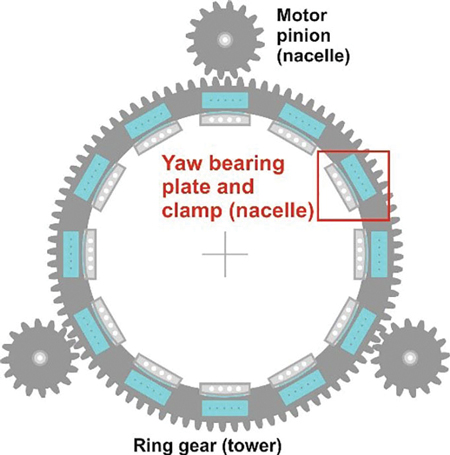

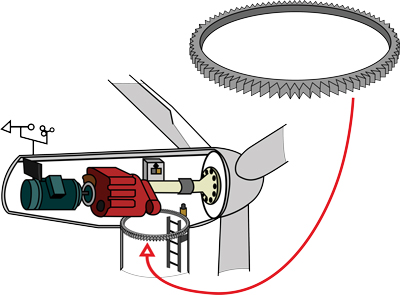

In Situ Method Makes Repairs More Economically Feasible

In Situ Method Makes Repairs More Economically FeasibleA new invention for repairing yaw rings in situ is expected to make a contribution to extending the lifespan of wind turbines. Developed by Danish machining expert CNC Onsite, the patented system means the yaw ring does not need to be replaced, eliminating the expensive, time-consuming and potentially detrimental disassembly of the rotor and nacelle.

By Søren Kellenberger, Sales Director, CNC Onsite, Denmark

- Category: Articles

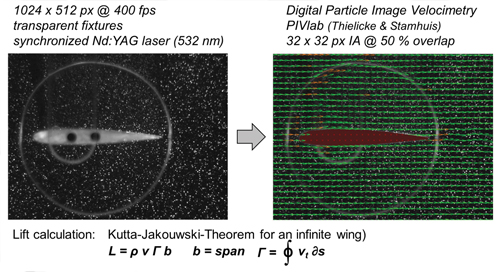

Technology Inspired by Large Seabirds Leads to Increased Lift at Low Wind Speed

Technology Inspired by Large Seabirds Leads to Increased Lift at Low Wind SpeedSince early 2019, the Albatrozz consortium has been active in the application of a principle that mimicks the landing behaviour of the albatross to increase the energy production of wind turbines especially at low wind speeds. Years of academic research have led to a patent and subsequently to governmental stimulation funding, and now the consortium is almost ready to do full-scale testing on a Vestas V52 wind turbine. This article describes the background story including technical details, plans and outlook.

By Eize J. Stamhuis, Albatrozz, the Netherlands

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.