European Project Helps to Shape the Future of Floating Wind

European Project Helps to Shape the Future of Floating WindFloating offshore wind has become a hot topic in the last few years. The technology promises access to ideal wind conditions previously out of reach, higher acceptance by society and less environmental impact compared with bottom-fixed wind foundations. Despite numerous advantages, no project has reached industrial scale yet. The main reason is the relative degree of technical immaturity and the total costs. Factors such as increased complexity resulting from the additional motion of floating platforms, added material demand for moorings and substructure, a lack of adequate port infrastructure and a lack of consensus on substructure design and mooring configuration, which prevent the benefit from production scaling effects, are some of the main reasons for this reality. The need for innovation is a strong driver within the research community to reduce these costs.

By Robert Behrens de Luna, Project Manager, FLOATECH Project, Germany

Within the European Commission funded project FLOATECH, the open-source simulation tool QBlade has been expanded to capture the complex physics around floating wind turbines. This simulation tool is currently being leveraged to develop and test control strategies especially tailored for floating turbines, which promises a decrease in the levelised cost of energy (LCOE).

The Challenge

The ChallengeThe success of floating turbine prototypes such as Hywind and FLOATGEN has been an important step towards improving the technology for profitable global deployment. In order for this trend to continue, we need a better understanding of the design requirements and restrictions of each of the different subsystems that make up a floating turbine. Ensuring comprehensive analysis of a fully coupled system is crucial to avoid any potential deterioration in the overall system performance resulting from improvements made at the subsystem level. Design and analysis tools therefore require sufficient accuracy and resolution of the coupled dynamics but also a high computational efficiency to allow their use in highly iterative design and optimisation processes of floating wind turbine systems. An example is the capability to resolve wake aerodynamics to improve the understanding of turbine–wake interaction in floating wind farms, which helps to improve control strategies and optimise farm layouts.

Uncertainty Reduction Through Advanced Simulation Capability

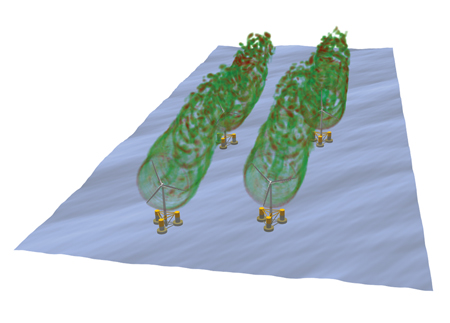

QBlade can help meet this requirement because it features a true multibody structural model combined with an advanced lifting-line free vortex wake aerodynamic method. As part of the FLOATECH project, QBlade has been expanded to include new hydrodynamic and substructure models that allow detailed aero-hydro-servo-elastic simulations of offshore floating wind turbines. This new model includes automatic calculation of hydrostatic forces for arbitrary substructure geometries and an interface to import hydrodynamic properties of substructures from external software (boundary element method codes), enabling the calculation of hydrodynamic forces in arbitrary conditions. Additionally, QBlade is able to model distributed hydrodynamic loads of flexible submerged elements based on the Morison equation. These features make QBlade a powerful tool for the design and simulation of floating turbines. In addition to the hydrodynamic models, QBlade was also expanded to include a higher-fidelity aerodynamic particle solver, which further improves the modelling of complex turbine–wake interactions.

QBlade can help meet this requirement because it features a true multibody structural model combined with an advanced lifting-line free vortex wake aerodynamic method. As part of the FLOATECH project, QBlade has been expanded to include new hydrodynamic and substructure models that allow detailed aero-hydro-servo-elastic simulations of offshore floating wind turbines. This new model includes automatic calculation of hydrostatic forces for arbitrary substructure geometries and an interface to import hydrodynamic properties of substructures from external software (boundary element method codes), enabling the calculation of hydrodynamic forces in arbitrary conditions. Additionally, QBlade is able to model distributed hydrodynamic loads of flexible submerged elements based on the Morison equation. These features make QBlade a powerful tool for the design and simulation of floating turbines. In addition to the hydrodynamic models, QBlade was also expanded to include a higher-fidelity aerodynamic particle solver, which further improves the modelling of complex turbine–wake interactions.

Increasing the Energy Output of Wind Turbine Pairs

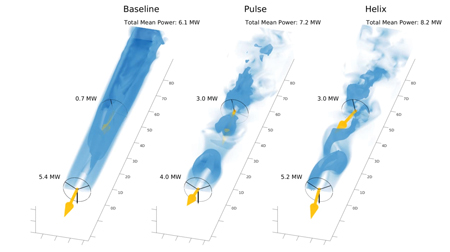

Increasing the Energy Output of Wind Turbine PairsQBlade enables the exploration of innovative control strategies that are on a conceptual stage or have higher technology readiness levels. The Wind Turbine and Wind Farm Control group at TU Delft has developed two control strategies: Helix and Pulse. These strategies aim to accelerate wake recovery by increasing turbulent mixing within the wake and thereby enhance wind farm annual energy production. To achieve this, both strategies use the blade pitch actuators – the Pulse strategy uses collective pitch action of the three blades, while the Helix strategy individually pitches each blade with a phase shift between signals. The effectiveness of these strategies has been demonstrated in previous studies that use higher-order computational fluid dynamics simulations. However, only a fully coupled tool like QBlade that models all important aspects (aero, servo, hydro and control) is capable of fully predicting the influence of these strategies on the floating system dynamics, the loads and the turbine–wake interaction.

Reducing Platform Motion and Loads

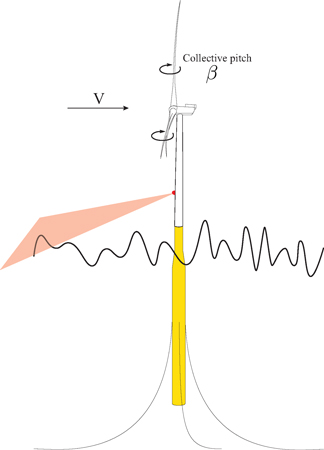

The collaboration between NextOcean, Technical University (TU) of Delft and TU Berlin introduces a further promising concept for advancing the economic viability of floating wind technology – active-wave-feed-forward control. Currently, radar technology is put in use by Next Ocean to limit the motion of maintenance and installation vessels. This allows for safe access to the gangway between ship and platform and enables safe operation of vessel-installed cranes. Within the project, this sensing technology will be repurposed to reduce the motion of a floating turbine due to incoming waves. The radar gives the turbine controller information on incoming waves, enabling the turbine to generate counteracting aerodynamic forces through synchronised blade pitch control. This has the potential to cut material costs for the tower. In this work package, QBlade provides an interface that facilitates the transmission of wave prediction data to the controller – as the radar would in a real environment – enabling the development of a control strategy by TU Delft’s researchers that fulfils this task. This innovation has significant potential to bring floating wind technology closer to achieving economic breakthroughs.

The collaboration between NextOcean, Technical University (TU) of Delft and TU Berlin introduces a further promising concept for advancing the economic viability of floating wind technology – active-wave-feed-forward control. Currently, radar technology is put in use by Next Ocean to limit the motion of maintenance and installation vessels. This allows for safe access to the gangway between ship and platform and enables safe operation of vessel-installed cranes. Within the project, this sensing technology will be repurposed to reduce the motion of a floating turbine due to incoming waves. The radar gives the turbine controller information on incoming waves, enabling the turbine to generate counteracting aerodynamic forces through synchronised blade pitch control. This has the potential to cut material costs for the tower. In this work package, QBlade provides an interface that facilitates the transmission of wave prediction data to the controller – as the radar would in a real environment – enabling the development of a control strategy by TU Delft’s researchers that fulfils this task. This innovation has significant potential to bring floating wind technology closer to achieving economic breakthroughs.

Development of Experimental Facilities

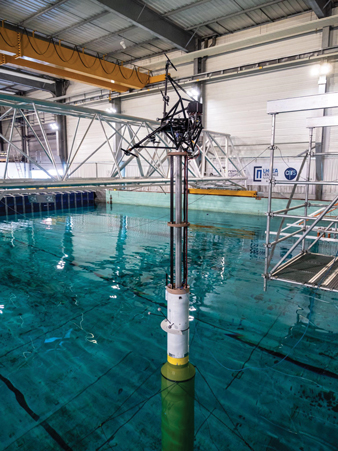

Development of Experimental FacilitiesIn order to validate these innovative technologies under realistic conditions, the LHEEA research department (Nantes Université, École Centrale de Nantes) and CNRS (Centre National de la Recherche Scientifique) are enhancing a software-in-the-loop (SIL) experimental set-up throughout FLOATECH. The set-up involves a floating spar platform installed and moored in a wave tank, with a flexible tower and a drone-propeller-based actuator replacing the traditional wind turbine rotor–nacelle assembly, with distributed rotors that generate the servo-aerodynamic forcing. During the experiment, real-time tracking of the platform’s motion from wave excitation and aerodynamic forces is conducted. This data is then transmitted to a parallel-running simulation suite, which calculates the aerodynamic forces of the turbine in real time, including the action of the rotor (blade pitch angle and generator torque). The resulting aerodynamic thrust force is fed back to the controlled thruster, enabling it to replicate the loads of the digital twin on the tower with minimal delay. As part of this project, the actuator is being upgraded from a simple one-component one to a six-component one, capable of reproducing the complete forces and moments experienced by a turbine rotor in a realistic fashion.

Proof of Concept in Lab and Real-Life Conditions

The feed-forward controller is being implemented in the controlled environment of the SIL experiment. Wave information is recorded from a previous campaign without a floating wind turbine present. This wave elevation time-series data obtained at the floater’s position is captured and used in the control system as an input, providing a preview of the wave elevation information, as Next Ocean’s radar technology would. Initial analysis of the experiment shows promising results in reducing platform motion, although further evaluation needs to be concluded for a comprehensive assessment. Additionally, Next Ocean’s radar technology has been installed on the FLOATGEN demonstrator – a 2MW floating wind turbine mounted on the BW Ideol’s floating foundation at the SEM-REV experimentation site northwest of Nantes. The radar is currently operational and actively tracking wave elevation data in the real conditions of the northern Atlantic. At the conclusion of the project, the collected data will be analysed, contributing to the creation of a valuable wave elevation database and validating the radar’s suitability for control applications in this context.

The feed-forward controller is being implemented in the controlled environment of the SIL experiment. Wave information is recorded from a previous campaign without a floating wind turbine present. This wave elevation time-series data obtained at the floater’s position is captured and used in the control system as an input, providing a preview of the wave elevation information, as Next Ocean’s radar technology would. Initial analysis of the experiment shows promising results in reducing platform motion, although further evaluation needs to be concluded for a comprehensive assessment. Additionally, Next Ocean’s radar technology has been installed on the FLOATGEN demonstrator – a 2MW floating wind turbine mounted on the BW Ideol’s floating foundation at the SEM-REV experimentation site northwest of Nantes. The radar is currently operational and actively tracking wave elevation data in the real conditions of the northern Atlantic. At the conclusion of the project, the collected data will be analysed, contributing to the creation of a valuable wave elevation database and validating the radar’s suitability for control applications in this context.

Economic Assessment of New Technologies

Economic Assessment of New TechnologiesAs a final objective within FLOATECH, the research centre Seapower is analysing the LCOE reduction potential gained by implementing the new control strategies. This analysis is being conducted within a newly developed cost modelling framework. Using QBlade, Seapower assesses material savings in a floating wind turbine by applying a wave-feed-forward controller compared with a conventional baseline controller. Additionally, it employs the Helix wake mixing technology in various realistic scenarios to determine the increased energy within the wake and the subsequent power output boost for a downstream turbine. The resulting cost analysis framework will be released as an open-source tool, aiding other researchers in evaluating their own innovative technologies. The FLOATECH consortium anticipates significant cost reductions through this research, enabling floating offshore wind technology to contribute to a greener future powered by renewable energy.

Biography of the Author

Robert Behrens de Luna holds a master’s degree in mechanical engineering and is currently a PhD candidate specialising in floating offshore wind at TU Berlin. He has previously conducted research on aeroelasticity in wind turbine tip extensions during a guest stay at DTU Wind Energy. Moreover, Robert works as the project manager for the FLOATECH project.

Robert Behrens de Luna holds a master’s degree in mechanical engineering and is currently a PhD candidate specialising in floating offshore wind at TU Berlin. He has previously conducted research on aeroelasticity in wind turbine tip extensions during a guest stay at DTU Wind Energy. Moreover, Robert works as the project manager for the FLOATECH project.