Power Performance Air Density Comparison Using Met Masts and Lidars

Power Performance Air Density Comparison Using Met Masts and LidarsAir density is critical for wind turbine energy predictions and power performance measurements. Typically, pressure, temperature and relative humidity sensors installed on a hub-height meteorological mast are used to calculate the air density.

By Ellie Weyer and Linda Sloka, UL Solutions, USA

The IEC 61400-12-1 standard for power performance testing requires a hub-height meteorological (met) mast or a ground-based remote sensing device (RSD) with a short met mast. In these cases, installing sensors on the met mast well above the ground is easy.

Industry confidence in RSDs continues to grow and may make met masts obsolete for power performance testing in simple terrain. Yet, accurate air density measurements will still be needed. This article compares alternate air density sources – distant met masts, lower heights on the same mast, and ground-based and nacelle-mounted lidar weather stations. Understanding impacts on air density and wind turbine energy measurements can help test planning and reduce costs for future power performance tests, particularly when stand-alone ground-based lidar and/or nacelle-mounted lidar are used instead of a hub-height met mast.

Methods

MethodsThree test sites in Texas and New Mexico in the USA were used for this study. The sites were in simple terrain and covered low, mid and high altitudes. The baseline case used the hub height (85 to 120 metres) to meet mast air density measurements, and each test case changed to the alternate measurement source for air density. All air density comparisons were performed at wind turbine hub height and accounted for temperature and pressure differences with height.

Individual measurements for temperature, pressure and humidity are compared. Then, the combined measurement of air density and its impact on measured wind turbine power curves are evaluated.

Temperature Comparison

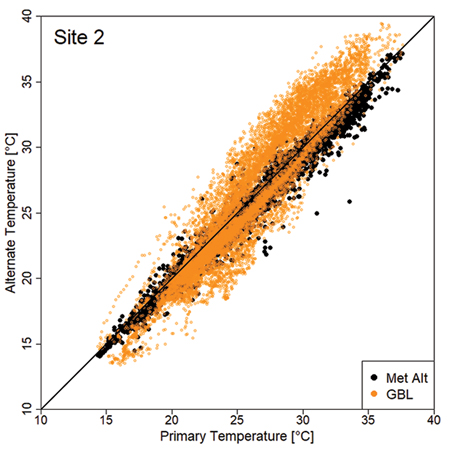

The average temperature difference for all test cases was within 1°C. Looking at Site 2 in Figure 1, we compared the primary temperature (x-axis) with two alternatives: a ground-level lidar weather station (orange) and a temperature sensor mounted at 55 metres on a met mast 9 kilometres away (black). As shown in the figure, both datasets have increased scatter in measured temperature; however, the average temperature difference is slight (1°C). The higher scatter in the lidar dataset (orange) compared with the distant met-mast dataset (black) indicates that ground-level temperature measurements are less predictive than temperature measurements at higher heights. Although both datasets were corrected to turbine hub height (105 metres), temperature extrapolation to hub height using a constant gradient misses nuances in atmospheric instability.

The average temperature difference for all test cases was within 1°C. Looking at Site 2 in Figure 1, we compared the primary temperature (x-axis) with two alternatives: a ground-level lidar weather station (orange) and a temperature sensor mounted at 55 metres on a met mast 9 kilometres away (black). As shown in the figure, both datasets have increased scatter in measured temperature; however, the average temperature difference is slight (1°C). The higher scatter in the lidar dataset (orange) compared with the distant met-mast dataset (black) indicates that ground-level temperature measurements are less predictive than temperature measurements at higher heights. Although both datasets were corrected to turbine hub height (105 metres), temperature extrapolation to hub height using a constant gradient misses nuances in atmospheric instability.

Pressure Comparison

The average pressure difference for the test cases was up to 4 millibars. These pressure differences are considered minor, because they are less than an 80-metre vertical pressure correction (~10 millibars).

The average pressure difference for the test cases was up to 4 millibars. These pressure differences are considered minor, because they are less than an 80-metre vertical pressure correction (~10 millibars).

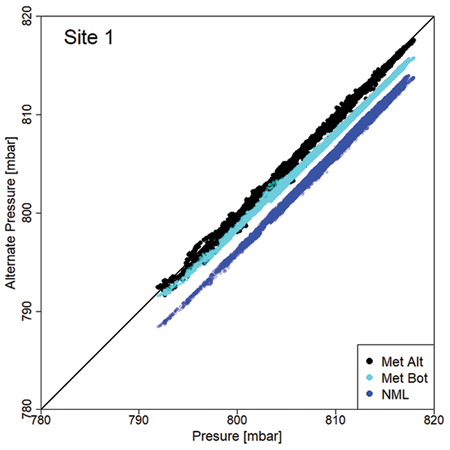

Looking at Site 1, Figure 2 shows data for pressure sensors mounted at the same height on a met mast 9 kilometres away (black), sensors mounted at a lower height on the same mast, corrected by 80 metres (cyan), and the nacelle lidar weather station (blue). The figure shows that none of the datasets have a noteworthy increase in scatter compared with the base case. Nearly no bias exists for the black dataset (< 1 millibar), indicating that pressure measurements at hub height are very accurate, even across large horizontal distances. A slight bias exists for the cyan dataset (2 millibars), indicating that the pressure correction method is imperfect even after correcting for height. The higher bias of the blue dataset (4 millibars) is expected due to the nacelle lidar location behind the rotor, with an aerodynamic pressure drop compared with the free stream.

Looking at Site 1, Figure 2 shows data for pressure sensors mounted at the same height on a met mast 9 kilometres away (black), sensors mounted at a lower height on the same mast, corrected by 80 metres (cyan), and the nacelle lidar weather station (blue). The figure shows that none of the datasets have a noteworthy increase in scatter compared with the base case. Nearly no bias exists for the black dataset (< 1 millibar), indicating that pressure measurements at hub height are very accurate, even across large horizontal distances. A slight bias exists for the cyan dataset (2 millibars), indicating that the pressure correction method is imperfect even after correcting for height. The higher bias of the blue dataset (4 millibars) is expected due to the nacelle lidar location behind the rotor, with an aerodynamic pressure drop compared with the free stream.Humidity Comparison

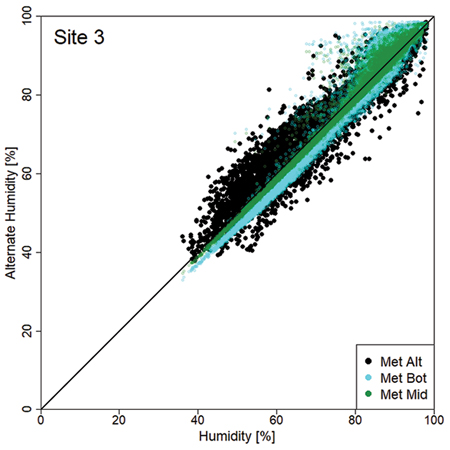

This study uses moist air density and measured humidity, aligning with industry best practices. The average humidity difference is within 6% for all comparisons. The available humidity comparisons for Site 3, Figure 3, are for sensors mounted on a met mast 9 kilometres away (black) and sensors mounted at 10 or 32 metres on the same mast (cyan, green). The humidity did not correlate well over height (cyan, green) or distance (black), as seen by the increased scatter in the figure. However, humidity has a smaller impact on calculated air density than temperature and pressure, so decreased reliability for humidity does not have as large an impact.

This study uses moist air density and measured humidity, aligning with industry best practices. The average humidity difference is within 6% for all comparisons. The available humidity comparisons for Site 3, Figure 3, are for sensors mounted on a met mast 9 kilometres away (black) and sensors mounted at 10 or 32 metres on the same mast (cyan, green). The humidity did not correlate well over height (cyan, green) or distance (black), as seen by the increased scatter in the figure. However, humidity has a smaller impact on calculated air density than temperature and pressure, so decreased reliability for humidity does not have as large an impact.

Air Density and Energy Comparison

The bias and spread of the individual measurements impact the bias and spread of the combined air density calculation. However, despite increased scatter and/or bias in the individual measurements, the average air density difference is maintained within 0.003kg/m3 for all sites. This is considered a slight air density difference. Often, power curve measurements will further round the selected site density or warranted power curve used to the nearest 0.01kg/m3.

The bias and spread of the individual measurements impact the bias and spread of the combined air density calculation. However, despite increased scatter and/or bias in the individual measurements, the average air density difference is maintained within 0.003kg/m3 for all sites. This is considered a slight air density difference. Often, power curve measurements will further round the selected site density or warranted power curve used to the nearest 0.01kg/m3.

More important than the air density difference is how the air density difference impacts the wind turbine’s measured power curve and energy output. The wind turbine’s expected power curve (i.e. wind speed on the x-axis and power on the y-axis) is a function of air density because there is more energy in an 8.0 m/s wind at high air density rather than low air density. The measured power curve accounts for this by density normalising the measured wind speed. The measured power curve is multiplied by an assumed wind speed distribution to calculate measured energy. In these cases, the impact of changing from the primary to the alternate air density is a change in energy of between −0.05 and +0.14%.

More important than the air density difference is how the air density difference impacts the wind turbine’s measured power curve and energy output. The wind turbine’s expected power curve (i.e. wind speed on the x-axis and power on the y-axis) is a function of air density because there is more energy in an 8.0 m/s wind at high air density rather than low air density. The measured power curve accounts for this by density normalising the measured wind speed. The measured power curve is multiplied by an assumed wind speed distribution to calculate measured energy. In these cases, the impact of changing from the primary to the alternate air density is a change in energy of between −0.05 and +0.14%.Conclusions

Although based on a small sample size, these results show that using alternate air density sources can cause a potential bias in air density measurement and energy comparison. Air density differences up to 0.003kg/m3 and energy differences up to 0.14% are noted, although neither is considered significant. In rare cases, this change in measured energy could differentiate between passing or failing a power performance warranty test. In other cases, this potential bias may be acceptable to all parties involved in the power performance test.

Although based on a small sample size, these results show that using alternate air density sources can cause a potential bias in air density measurement and energy comparison. Air density differences up to 0.003kg/m3 and energy differences up to 0.14% are noted, although neither is considered significant. In rare cases, this change in measured energy could differentiate between passing or failing a power performance warranty test. In other cases, this potential bias may be acceptable to all parties involved in the power performance test.

Biographies of the Authors

Ellie Weyer and Linda Sloka are the subject matter experts in North America for wind turbine power performance testing at UL Solutions. They each have 25 years of experience in the wind industry and are focused on applying the IEC 61400-12-1 and 61400-50 standards for power performance and contractual performance guarantees.

Ellie Weyer and Linda Sloka are the subject matter experts in North America for wind turbine power performance testing at UL Solutions. They each have 25 years of experience in the wind industry and are focused on applying the IEC 61400-12-1 and 61400-50 standards for power performance and contractual performance guarantees.