Using Wind Turbine Nacelle-Based Anemometers

Using Wind Turbine Nacelle-Based AnemometersPower performance testing (PPT), also known as ‘power curve verification’ or ‘power curve testing’, is an on-site field test of operating wind turbines to verify the OEM’s provided power curve(s) defined in the project’s turbine supply agreement (TSA). The testing is prescribed under industry standards, namely the IEC 61400-12 series of standards, and further defined by the OEM in the TSA. Typically, it is the owner/operator who is responsible for PPT implementation, but the main driver for the test is financial investors seeking assurance that their investment will perform as expected. The traditional and typical method of PPT requires installing a meteorological (met) tower in a location that is not affected by the wakes of the operating wind turbines. The wind data collected from this free-stream, unwaked met tower is understood to be representative of the wind characteristics of its associated wind turbine. The measured power curve is determined by concurrent measurements of hub height, wind speed and turbine power output.

By Daniel W. Bernadett, Global Director of Engineering, ArcVera Renewables, USA

Power performance testing (PPT) is both time-consuming and expensive. If the cost of a meteorological (met) tower were eliminated, the cost of PPT could be significantly reduced. While not a new idea, this article explores the advantages of using nacelle-based anemometers for PPT. PPT testing has meaningful value, and a less costly testing methodology would enable the industry to conduct tests on more projects and more turbines, providing significant value to all project stakeholders.

New Thinking for PPT: Using Wind Turbine Nacelle-Based Anemometers

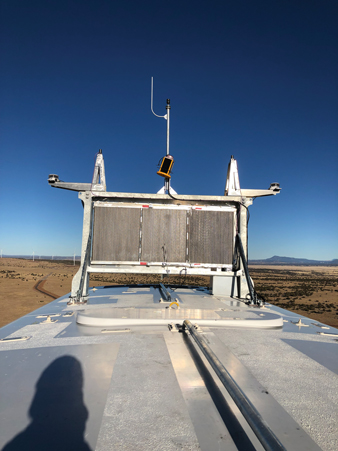

New Thinking for PPT: Using Wind Turbine Nacelle-Based AnemometersAnemometer data acquired using nacelle-based anemometers is available for every turbine throughout a project’s life, and engineers focusing on wind turbine performance have long sought to use this data for PPT. In 2013, a standard was published for PPT using nacelle-based anemometers (IEC 61400-12-2). The purpose of this standard was to provide guidance on using nacelle-based anemometers for PPT. However, questions regarding the uncertainty of nacelle anemometer measurements have constrained the use of this standard within the industry. The primary concern regards the uncertainty of measuring wind speed at a single wind turbine. This concern is addressed by measuring 60 to 100% of the wind turbines. Uncorrelated uncertainties, including the measurement variation due to terrain-induced effects, can be reduced by the square root of the number of wind turbines tested. Since these uncertainties are difficult to control, reducing them through increasing the number of measurements provides significant value to the process. Correlated uncertainties include the nacelle mounting method, anemometer measurement and calibration data, the original nacelle transfer function, and the method of measuring power output. Even though these uncertainties are not reduced by increasing the number of turbines measured, they can be actively controlled by careful test planning and execution. If we assume that uncorrelated uncertainties account for half of the total, then half the total uncertainty can be reduced by the square root of the number of turbines tested.

For example, if the total uncertainty of nacelle anemometer readings were 11 to 17%, with correlated and uncorrelated uncertainties each contributing 8 to 12% uncertainty, testing 64 turbines would result in an overall uncertainty of 8 to 12% because the uncorrelated portion becomes vanishingly small when combined in quadrature. This allows an OEM to offer a reasonable PPT warranty (88 to 92%). The typical uncertainty for met-tower-based PPTs is 6 to 8%, which results in warranty levels of 92 to 94%. While warranty levels for nacelle anemometer testing may be lower than traditional met tower testing, the cost reduction may offset this warranty level. Lidar offers cost reduction relative to traditional met tower testing, but lidar cannot be used in complex terrain. OEMs now offer power performance warranties using nacelle anemometer testing in complex terrain. Thus, nacelle anemometer testing offers a cost-effective solution in both simple and complex terrain.

Testing all Turbines in a Farm Enhances Performance and Revenue

Testing all Turbines in a Farm Enhances Performance and RevenueTraditional, met-tower-based PPT measures only a handful of turbines, and there is no way to tell whether the non-tested turbines perform as well as the tested turbines. Nacelle-based anemometer testing allows for cost-effective performance testing of every turbine in the wind farm, ensuring uniform performance by all turbines. The same nacelle anemometers can be used to monitor and maintain performance as the wind turbine blades degrade and changes are made to the controller and pitch system. Asset managers may also find value by integrating a nacelle-based test into the wind project’s total quality management process, leading to enhanced turbine performance and increased project revenue.

Finally, a Way to Cost-Effectively Ensure Turbine Performance

Most project developers do not expect to collect liquidated damages based on a PPT result, leading many developers to skip PPT tests altogether. However, maximising project revenue requires ensuring that every turbine is performing at its peak potential every hour of every day. Testing a large sample of turbines more effectively accomplishes that goal while reducing the ultimate cost of a PPT.

Most project developers do not expect to collect liquidated damages based on a PPT result, leading many developers to skip PPT tests altogether. However, maximising project revenue requires ensuring that every turbine is performing at its peak potential every hour of every day. Testing a large sample of turbines more effectively accomplishes that goal while reducing the ultimate cost of a PPT.

Financial investors rely on PPTs to ensure that the wind energy project will perform as defined in the contract. Only through a PPT can OEMs be held accountable for underperformance. Traditional, met-tower-based PPTs are well understood and are most often used in the wind energy industry, but the number of actual tests is relatively low due to the significant investment required. Considering the nacelle-based anemometer PPT methodology, as outlined in the IEC 61400-12-2 standard, projects can reduce the risk of underperformance at a lower cost. The wind industry will benefit from a testing volume that is commensurate with the scale of the projects – more tests will provide a more informed basis for determining how a wind farm is performing and allow any problems to be quickly corrected. By catching problems quickly, the revenue from a project can be continually optimised.

Summary

PPT is both time-consuming and expensive. PPT using nacelle-based anemometers under the IEC 61400-12-2 standard offers a lower-cost, total project PPT solution. PPT testing has meaningful value, and a less costly testing methodology would enable the industry to conduct tests on more projects and more turbines, providing significant value to all project stakeholders.

PPT is both time-consuming and expensive. PPT using nacelle-based anemometers under the IEC 61400-12-2 standard offers a lower-cost, total project PPT solution. PPT testing has meaningful value, and a less costly testing methodology would enable the industry to conduct tests on more projects and more turbines, providing significant value to all project stakeholders.

Biography of the Author

Dan Bernadett is ArcVera Renewables’ Global Director of Engineering. Mr Bernadett is an industry veteran with over 30 years of experience in the wind industry. Throughout his career, Mr Bernadett has assembled a formidable base of experience and expertise in specialised areas ranging from PPT to diagnosis of plant performance issues. Mr Bernadett is an expert on turbine technical issues, plant design, and resource assessment. His extensive range of industry experience gives Mr Bernadett an exceptional ability to solve the diverse problems that can affect operational performance and project profitability.

Dan Bernadett is ArcVera Renewables’ Global Director of Engineering. Mr Bernadett is an industry veteran with over 30 years of experience in the wind industry. Throughout his career, Mr Bernadett has assembled a formidable base of experience and expertise in specialised areas ranging from PPT to diagnosis of plant performance issues. Mr Bernadett is an expert on turbine technical issues, plant design, and resource assessment. His extensive range of industry experience gives Mr Bernadett an exceptional ability to solve the diverse problems that can affect operational performance and project profitability.