Problems Faced in Service Life Estimation of Blade Bearings

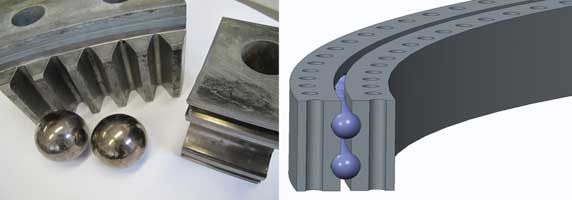

The blade bearings of wind turbines allow the required oscillation to control the loads and power of the wind turbine. The pitch system brings the blade to the desired position by adapting the aerodynamic angle of attack. The pitch bearing, which is connected to the blade and the hub of the turbine, is subjected to high axial forces and bending moments. The conditions of these bearings are unique and most standards to estimate bearing service life are designed for rotating bearings and do not consider the oscillation. This article gives a brief overview of the current problems of blade bearings. The article focuses on the tribological challenges like fatigue life calculation of oscillating bearings, different wear damage modes like false brinelling and fretting wear, grease lubrication and the contact conditions occurring under different operating environments.

The blade bearings of wind turbines allow the required oscillation to control the loads and power of the wind turbine. The pitch system brings the blade to the desired position by adapting the aerodynamic angle of attack. The pitch bearing, which is connected to the blade and the hub of the turbine, is subjected to high axial forces and bending moments. The conditions of these bearings are unique and most standards to estimate bearing service life are designed for rotating bearings and do not consider the oscillation. This article gives a brief overview of the current problems of blade bearings. The article focuses on the tribological challenges like fatigue life calculation of oscillating bearings, different wear damage modes like false brinelling and fretting wear, grease lubrication and the contact conditions occurring under different operating environments.

By Fabian Schwack and Prof. Dr.-Ing. Gerhard Poll, Institute of Machine Design and Tribology, Germany

Cost of Energy

The expected life of the components of a wind turbine affect the cost of energy, which is an important factor for wind to be competitive against other energy sources. Blade bearings have significant effect on costs. Therefore, life estimation of blade bearings needs to be improved for higher economic efficiency.