Ring-Shaped Bearingless Generator with Buoyant Rotor and Modular Structure

In wind turbines, bearing failures have been a continuing problem and have accounted for a significant proportion of all failures. Bearing-related downtime is among the highest of all components of wind turbines. The location of wind turbines is moving offshore. However, to access offshore sites is difficult and thus wind turbines with high reliability and availability are required. Direct-drive wind generators are argued to have higher reliability and availability than geared generators. However, direct-drive generators require a large diameter, which results in a large mass and high cost, in order to get a high torque rating compared to geared generators. It is disadvantageous in terms of manufacture and maintenance to construct direct-drive generators with a large diameter as a one-body structure. In scaling up the power of direct-drive generators, the structural part becomes dominant in the total mass of the generators. Therefore, it is necessary to find a solution to significantly reduce bearing failures and structural mass, and to facilitate manufacture and maintenance for large direct-drive wind generators.

In wind turbines, bearing failures have been a continuing problem and have accounted for a significant proportion of all failures. Bearing-related downtime is among the highest of all components of wind turbines. The location of wind turbines is moving offshore. However, to access offshore sites is difficult and thus wind turbines with high reliability and availability are required. Direct-drive wind generators are argued to have higher reliability and availability than geared generators. However, direct-drive generators require a large diameter, which results in a large mass and high cost, in order to get a high torque rating compared to geared generators. It is disadvantageous in terms of manufacture and maintenance to construct direct-drive generators with a large diameter as a one-body structure. In scaling up the power of direct-drive generators, the structural part becomes dominant in the total mass of the generators. Therefore, it is necessary to find a solution to significantly reduce bearing failures and structural mass, and to facilitate manufacture and maintenance for large direct-drive wind generators.

By Dr Deok-je Bang, Korea Electrotechnology Research Institute, South Korea

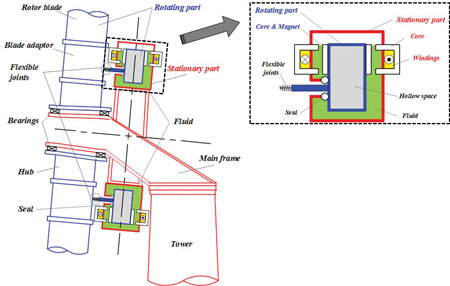

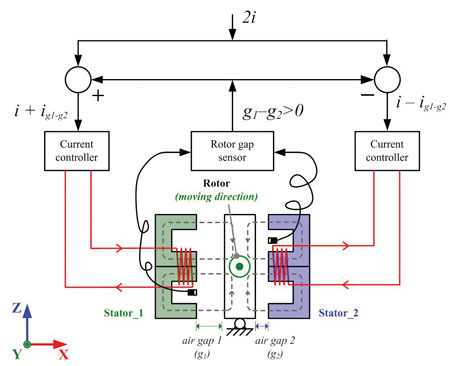

In this article, a new generator concept, a ring-shaped bearingless permanent magnet (PM) generator with a buoyant rotor and magnet and core modules, is described as a solution to significantly reduce the bearing failures and the structural mass, and to facilitate manufacture and maintenance for large direct-drive wind turbines.

In this article, a new generator concept, a ring-shaped bearingless permanent magnet (PM) generator with a buoyant rotor and magnet and core modules, is described as a solution to significantly reduce the bearing failures and the structural mass, and to facilitate manufacture and maintenance for large direct-drive wind turbines.