- Category: Articles

Making Oil and Gas Production in the Deep Blue Greener

Making Oil and Gas Production in the Deep Blue GreenerA recent project has investigated the potential for a renewable energy solution to reduce the emissions associated with the production of offshore oil and gas in the North Sea in a variety of scenarios. The project, involving Lundin Energy Norway, Floating Power Plant, Cefront Technologies, APL-NOV, Semco Maritime, Aalborg University and DNV GL, explored technical, economic and regulatory aspects of combining the offshore renewable energy and oil and gas sectors.

By Chris McConville, Anders Køhler and Morten Egedal, Floating Power Plant, Denmark

- Category: Articles

ABIBA, a FlowChange Opportunity Project

ABIBA, a FlowChange Opportunity ProjectThe highest increase in annual yield a wind turbine can obtain is by increasing the rotor diameter. This is because the increase in wind power follows a mathematical ‘power of 2 law’ based on the diameter. For existing blade lengths and for the turbines that have already been running for a while, improvement is also possible by the use of flow changers. The amount of improvement is not to be underestimated and can bring a lot – at least up to 2.5% annual yield.

By Edo Kuipers, We4Ce, the Netherlands

- Category: Articles

How to Evaluate the Technical Risks

How to Evaluate the Technical RisksAlmost 50% of installed wind capacity in the USA is at least eight years old, accounting for approximately 60GW of operational projects. Unlike greenfield development, these projects have been operating for several years, which provides valuable insight into topics such as project performance, operating costs and revenue, community relations, environmental risks, and other key aspects.

By Jeremy Tchou, Director for Due Diligence, UL, USA

- Category: Articles

Design of Foundations for Next Generation Wind Turbine Generators

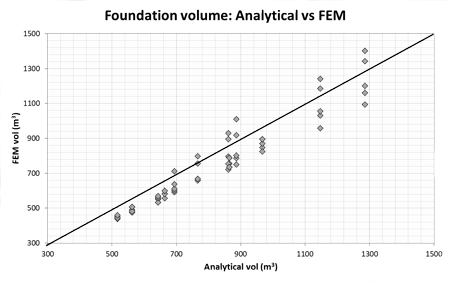

Design of Foundations for Next Generation Wind Turbine GeneratorsLarger turbines suppose an increase in loads that finally requires more prominent foundations. Those dimensions lead to flexible behaviour. With the current foundation volumes, we are at the boundary of applicability of some analytical expressions widely used in foundation geotechnical and structural calculations, especially in the early stages of design, as they assume the foundation to be a rigid body. Two possible scenarios arise. If the analytical expressions are on the safe side that will lead to overpricing with an overestimated foundation volume. On the other hand, analytical expressions could lead to unsafe foundation design.

By Matias Campos, AZTEC Engineering, USA and Maria Collado, TYPSA, Spain

- Category: Articles

Demonstrating Traceability and Proving Accuracy of a Lidar-Only Methodology

Demonstrating Traceability and Proving Accuracy of a Lidar-Only MethodologyA recent industry poll of almost 1,000 wind industry professionals reported that the remote sensing device (RSD) ‘lidar’ was being used standalone, i.e. without any additional on-site met masts or anemometry, in simple terrain for wind resource assessment in the development of wind energy projects by almost two-thirds of those responding. Much of this confidence can be traced back to the DNV GL ‘Stage 3’ statement in the roadmap for RSDs that allows for a standalone ZX 300 Wind Lidar, since October 2012, to be used in this way. In comparison, when considering the use of any lidar in complex terrain, less than one-third of those responding reported using the lidar standalone; instead, it would be complemented by additional on-site anemometry such as a met mast. In order for the industry to take advantage of the many additional benefits that lidars provide, the challenge was set: how can we as an industry demonstrate the traceability and prove the accuracy of a lidar-only methodology in complex terrain?

By Tristan Clarenc, Johannes Cordes, Alex Woodward, Scott Wylie

- Category: Articles

American Laboratory Tests, Experiments in Norway and Possible Large-Scale Demonstration

American Laboratory Tests, Experiments in Norway and Possible Large-Scale DemonstrationAn American research report led to the elimination of eagle deaths on the Norwegian island of Smøla. A review demonstrates that with today’s larger wind turbines, three black turbine blades per wind turbine can give at least as good results as the Norwegian experiment with one black blade. Given the importance of the appearance of the landscape to those viewing it, the former option is preferable.

By Staffan Engström, Managing Director, Ägir Konsult, Sweden

- Category: Articles

A Road Map to Successful and Conclusive Wind Turbine Improvement Projects

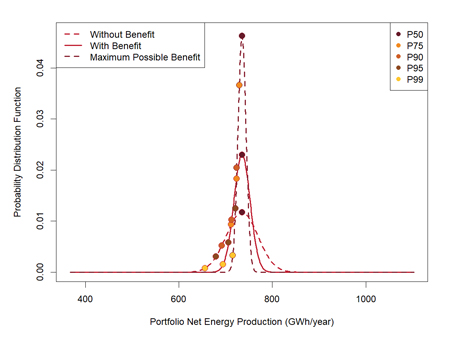

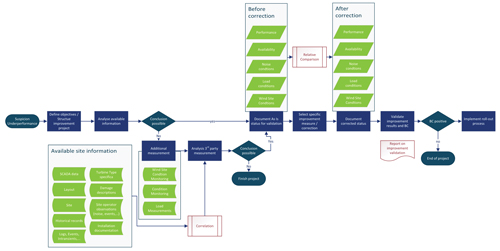

In times of zero subsidy bids and lowest cost of energy competition in the wind industry the margins of wind farm business cases are becoming rather tight. It is not enough anymore to simply keep the availability of the wind turbines at a reliable and high level to meet the business case expectations. This paves the way for wind turbine optimisation measures to regain the losses of 5 to 15% that a wind turbine might suffer and to tap additional performance potential hidden in the turbine design. In addition, there is usually an indirect added value, as such improvement measures usually not only increase the annual energy production (AEP) but also might reduce loads and stress in the wind turbine components. This article describes which particular rotor-based, wind turbine performance optimisation measures are available today, how to validate the AEP gains and how to get support to implement AEP improvements at scale (fleetwide) by means of monitoring and data analysis platforms – in this particular case, Power Factors’ Drive platform, a technical asset management and computerised maintenance management system.

In times of zero subsidy bids and lowest cost of energy competition in the wind industry the margins of wind farm business cases are becoming rather tight. It is not enough anymore to simply keep the availability of the wind turbines at a reliable and high level to meet the business case expectations. This paves the way for wind turbine optimisation measures to regain the losses of 5 to 15% that a wind turbine might suffer and to tap additional performance potential hidden in the turbine design. In addition, there is usually an indirect added value, as such improvement measures usually not only increase the annual energy production (AEP) but also might reduce loads and stress in the wind turbine components. This article describes which particular rotor-based, wind turbine performance optimisation measures are available today, how to validate the AEP gains and how to get support to implement AEP improvements at scale (fleetwide) by means of monitoring and data analysis platforms – in this particular case, Power Factors’ Drive platform, a technical asset management and computerised maintenance management system.By Karl Fatrdla, Power Factors and Karl Fatrdla Consulting, Austria

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.