Enhancing Reliability and Reducing LCOE of Drive-Trains

Enhancing Reliability and Reducing LCOE of Drive-Trains

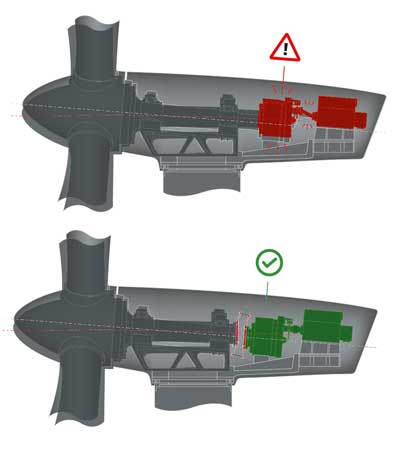

Advances in design, materials and drive-train testing have resulted in substantial improvements of wind turbine reliability, particularly in the 2–4MW class [1]. But with continuous growth in size of turbines, the risk of gearbox damage appears to be back on the agenda. Further upscaling of conventional drive-train designs is limited and alternative architectures might be required. A flexible element at the low-speed shaft allows the gearbox to be mounted rigidly to the main frame and relieves the gearbox from unnecessary stress and fatigue. The author of this article was part of a team that recently presented the results of a load study of such a system [2]. The focus of the current article is on a commercial study with the objective to identify the potential of reducing operational cost (OPEX) and enhancing levelised cost of energy (LCOE), using the example of a 6MW offshore wind turbine.

By Alexander Kari, Geislinger GmbH, Austria