A Grease with Low Base Oil Viscosity Improves Main Bearing Lubrication

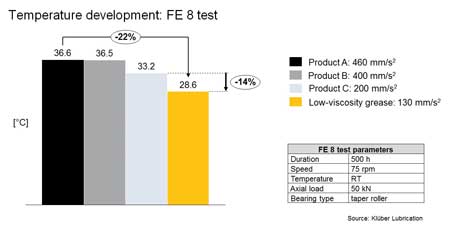

The lubrication of main bearings in wind turbines is a difficult business. The lubricant has to cope with false brinelling, with challenging operating aspects such as high loads and varying temperatures, and with the need to protect components against wear. Last, but not least, lubricants have to be useable in centralised  lubricating systems. The classical approach in wind turbine main bearing lubrication has been to use greases with a high base oil viscosity, which were regarded as the optimum. Meanwhile, bench tests and field experience have shown that greases with a low base oil viscosity (i.e. in the range of 130–150mm/s2) can protect the bearing better than other lubricants. The key to success is the combination of the low-viscosity base oil with suitable extreme pressure and antiwear additives.

lubricating systems. The classical approach in wind turbine main bearing lubrication has been to use greases with a high base oil viscosity, which were regarded as the optimum. Meanwhile, bench tests and field experience have shown that greases with a low base oil viscosity (i.e. in the range of 130–150mm/s2) can protect the bearing better than other lubricants. The key to success is the combination of the low-viscosity base oil with suitable extreme pressure and antiwear additives.

By Thomas Jørgensen, Klüber Lubrication, Germany