New Design and Validation Methodologies Improving Blade Airfoil Efficiency

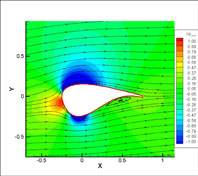

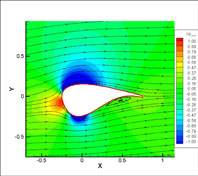

Gamesa has produced a new high efficiency blade design for the next generation of wind turbines. The advanced aerodynamics are a result of finding the best compromise between reducing blade-load levels and noise levels and maximising total annual energy production. By applying 3D CFD techniques, its own wind turbine experience, and technologies and methods to develop aerofoil efficiency, Gamesa has increased the expected improvement curve performance by 8% since its first design in the late 1990s. The final design also takes the three-dimensional effects that appear at both the root and the tip into consideration. Finally, validation is carried out in wind tunnels to verify the measurements of the advanced aerodynamics resulting from the new design.

Gamesa has produced a new high efficiency blade design for the next generation of wind turbines. The advanced aerodynamics are a result of finding the best compromise between reducing blade-load levels and noise levels and maximising total annual energy production. By applying 3D CFD techniques, its own wind turbine experience, and technologies and methods to develop aerofoil efficiency, Gamesa has increased the expected improvement curve performance by 8% since its first design in the late 1990s. The final design also takes the three-dimensional effects that appear at both the root and the tip into consideration. Finally, validation is carried out in wind tunnels to verify the measurements of the advanced aerodynamics resulting from the new design.

By Ignacio Romero Sanz, Chief Functional Engineer, and Juan Diego Díaz Vega, Marketing Director, Gamesa, Spain

Gamesa has produced a new high efficiency blade design for the next generation of wind turbines. The advanced aerodynamics are a result of finding the best compromise between reducing blade-load levels and noise levels and maximising total annual energy production. By applying 3D CFD techniques, its own wind turbine experience, and technologies and methods to develop aerofoil efficiency, Gamesa has increased the expected improvement curve performance by 8% since its first design in the late 1990s. The final design also takes the three-dimensional effects that appear at both the root and the tip into consideration. Finally, validation is carried out in wind tunnels to verify the measurements of the advanced aerodynamics resulting from the new design.

Gamesa has produced a new high efficiency blade design for the next generation of wind turbines. The advanced aerodynamics are a result of finding the best compromise between reducing blade-load levels and noise levels and maximising total annual energy production. By applying 3D CFD techniques, its own wind turbine experience, and technologies and methods to develop aerofoil efficiency, Gamesa has increased the expected improvement curve performance by 8% since its first design in the late 1990s. The final design also takes the three-dimensional effects that appear at both the root and the tip into consideration. Finally, validation is carried out in wind tunnels to verify the measurements of the advanced aerodynamics resulting from the new design.By Ignacio Romero Sanz, Chief Functional Engineer, and Juan Diego Díaz Vega, Marketing Director, Gamesa, Spain