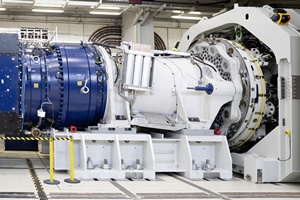

Flender has integrated a new production line in its factories in Voerde, Germany and in Tianjin, China at which they are manufacturing and assembling complete drivetrains.

Flender has integrated a new production line in its factories in Voerde, Germany and in Tianjin, China at which they are manufacturing and assembling complete drivetrains.The new production line requires new testing capabilities to be able to validate the quality and performance of the products. Flender has chosen a test system that can perform End- Of-Line (EOL) testing of all drivetrains prior to shipment. The new EOL test benches, delivered by R&D Test Systems, are based on the electrical back-to-back principle, which means that Flender can set up two full drive trains opposite each other and test them simultaneously. With this setup, it is possible on each factory to fully test 4 drivetrains in approx. 26 hours, as each test circle takes around 8 hours and the exchange of two drivetrains takes around 5 hours. The exchange time also covers removal of electrical power cables, oil lubrication hoses, cooling hoses, cables for DAQ and control system as well as all mechanical connections.