|

|

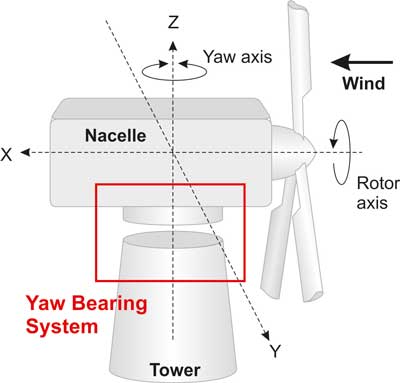

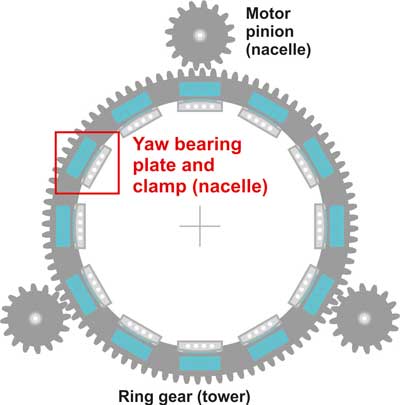

After remotely monitoring several thousand wind turbines over the past 10 years, most of the wind turbine faults detected and diagnosed by the Brüel & Kjær Vibro Surveillance Centres have been related to the drive train. In this article, two case studies are given where the faults were detected and diagnosed in an entirely different but important component – the yaw bearing system. It is this system that bears the enormous static and dynamic loads of the nacelle and blades, and allows the nacelle to align itself into the wind.

By Mike Hastings, Senior Application Engineer, Brüel & Kjær Vibro, Denmark