A wind turbine nacelle made from structural fabric? A tower made from composites? Blades with metal mesh inserts for structural rigidity? They might not be that far away. The greatest challenge for wind turbine blade structural and manufacturing engineers is to implement the idealised performance and noise-mitigated designs of aerodynamics engineers. Limitations of previous generations of manufacturing technology and the reliance on lower-cost materials have limited the type of spar/shear web structures which could be used.

A wind turbine nacelle made from structural fabric? A tower made from composites? Blades with metal mesh inserts for structural rigidity? They might not be that far away. The greatest challenge for wind turbine blade structural and manufacturing engineers is to implement the idealised performance and noise-mitigated designs of aerodynamics engineers. Limitations of previous generations of manufacturing technology and the reliance on lower-cost materials have limited the type of spar/shear web structures which could be used.

By Philip Totaro, Founder & CEO, IntelStor, LLC

With the forthcoming developments of additive manufacturing and 3D printing, hybrid material blades with performance and structural characteristics which seem like science fiction will become a reality within the next two years.

The concept behind hybrid material use is to allow for variation of material density at specific points of the blade in order to minimise weight while optimising structural integrity. For instance, the spar/webs or the entire root could be made of a high modulus glass or carbon where loads are higher, while utilising a more conventional E-glass outboard in order to save cost and leverage manufacturing CapEx investments/infrastructure already in place.

However, as turbines continue to push the power rating envelope and power density needs to be maintained in order to offer a competitive product, rotor size must correspondingly grow to previously unheard of proportions for onshore turbines.

IntelStor’ MKT Prism™ has been used to analyse the growing trend to shift towards IEC Class II and III turbines, along with the growth in power rating. The results indicate that at 4–4.5MW a 135–160 metres onshore rotor diameter would be needed for competitive Class II and III turbines. This rivals the current generation of offshore blades, which are being constructed with significant carbon reinforcement and typically a root diameter larger than the onshore transportable limit of about 4.2 metres.

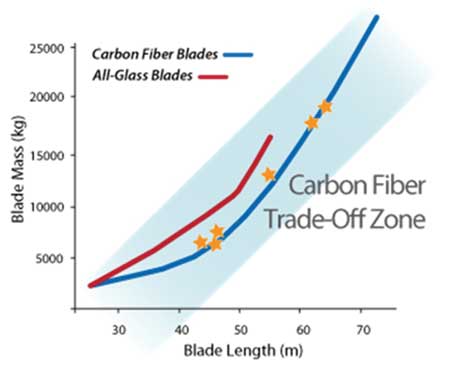

Clearly a new generation of technology will be required to push turbines to a higher level, and hybrid material combinations are poised to take a prime role. As ZOLTEK has noted in its analyses of the carbon versus glass trade-off, there are points at which carbon blade mass can be reduced in comparison with glass blades, particularly as blade length extends well beyond the 50 metre threshold.

The challenge of implementation has been one of cost, where only the longest blades (typically for offshore) could leverage carbon. Now with the advent of more advanced manufacturing techniques such as vacuum assisted resin transfer moulding (VARTM), carbon pre-pregs can be more easily implemented for longer onshore blades.

Current developments in hybrid materials and 3D printing are still in their infancy, with the majority of innovations still in the technology readiness level (TRL) 3–5 range, according to analysis by IP Prism. But these advanced manufacturing techniques will allow for the integration of structural, aerodynamic and noise mitigating features.

Metal–matrix composites have been widely used in the aerospace sector for many years, and represent an opportunity to leverage the technology and manufacturing techniques for wind now that the cost has been reduced to an acceptable level.

Technology development is poised to have a revolutionary impact on products being introduced in the next two years.