Effective Reduction Using a Low-Speed Coupling Made of Advanced Composites

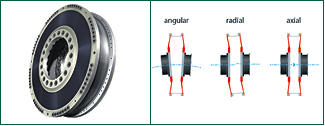

Poor drive-train reliability is still one of the main hurdles to get over in order to achieve a more competitive cost for wind energy. Many surveys confirm that gearbox failure rates are moderate compared to other components but, once a failure occurs, it leads to the highest downtime and a considerable loss of energy production. According to the results of investigations carried out by GL Garrad Hassan regarding the relative cost of energy, the reduction of gearbox failures rates by 50% would save revenue losses by almost 40% compared to the initial capital cost of the gearbox. Joint investigations by the National Renewable Energy Laboratory (NREL) and Alstom, with the target of improved drive-train reliability, have shown that non-torque loads (bending moments) can significantly affect the reliability of the gearbox. Non-torque loads are caused by aerodynamic loads, rotor overhung weight and drive-train weight, and occur independently of the drive-train concept. Low-speed couplings are pictured as a potential remedy for new drive-train layouts to solve the problem ‘outside the gearbox’.

Poor drive-train reliability is still one of the main hurdles to get over in order to achieve a more competitive cost for wind energy. Many surveys confirm that gearbox failure rates are moderate compared to other components but, once a failure occurs, it leads to the highest downtime and a considerable loss of energy production. According to the results of investigations carried out by GL Garrad Hassan regarding the relative cost of energy, the reduction of gearbox failures rates by 50% would save revenue losses by almost 40% compared to the initial capital cost of the gearbox. Joint investigations by the National Renewable Energy Laboratory (NREL) and Alstom, with the target of improved drive-train reliability, have shown that non-torque loads (bending moments) can significantly affect the reliability of the gearbox. Non-torque loads are caused by aerodynamic loads, rotor overhung weight and drive-train weight, and occur independently of the drive-train concept. Low-speed couplings are pictured as a potential remedy for new drive-train layouts to solve the problem ‘outside the gearbox’.

By Alexander Kari, Geislinger GmbH, Austria